Multifunctional motor sensors

Multifunctinal motor sensor (AMS300 series)Product introduction

【Purpose and effect】

Multifunction motor sensor realizes rationalizations and efficiency improvements by monitoring the electric power of the motor of a machine tool, multi-tasking machine or lathe, etc, and judging the situation.

| Judged items | Rationalization・Efficiency improvement |

|---|---|

| (1)Galling of Cutting tool | Exchanging cutting tool by judging the applicant limit is possible.(Usually prescribed frequencial exchange) |

| (2)Deficit of Cutting tool | Preventing the outflow of defective products and decrease of complaint cost are possible. |

| (3)Best conditions of cutting work | Maximization of applicant limit Minimization of consumption of cutting tool. |

| (4)Abnormal condition of machine | Preventing the trouble of machine and extending of applicant limit are possible. |

【Judging method】

(1)Judging upper and lower limit of wave

Setting upper/lower threshold following the loading pattern is possible. It monitor the normal galling of tool and control the time for replacement.

(2)Judging rate of change

Detecting deficit and abnormal galling of cutting tool are possible.It can ignore the normal galling.

(3)Judging comparative value

Judged by the electric power which is subtracted no-load drive electric power. The electric power of cutting work can be measured without no-load electric power.

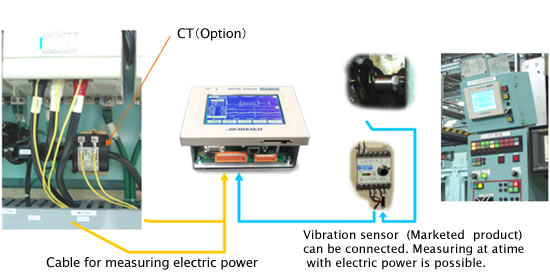

【Installation】

【Product specification】

| Rating | Power suply | DC24V(Handy type AC100V) | |

|---|---|---|---|

| Maximum electric power consumption | 15w | ||

| Operation temparature | 0~40℃ | ||

| Basic function | Measuring object | ・Three-fhase motor erectric power 0.4kw~132kw×1 | |

| (Inverter,servo are possible) | |||

| ・Analog signal DC0~5V×2 | |||

| Judging function | 4 methods(Wave pattern/Comparative value/Maximum value/ Rate of change )Measuring in a time is possible. | ||

| Internal/Outernal/Manual/Automatic/Nothing/In-Outarnal | |||

| Trigger | |||

| Sample frequency | 3ms~2000ms(Analog : 1ms~) | ||

| Number of samples | 2~2000points | ||

| Data memory | Data record | Maximum change/Maximum value/Rate of change. | |

| Each are maximum 32,000cycles record. | |||

| Abnormal record | Happened date,time/Number of cycles/Abnormal pattern | ||

| Maximum 1000 cycles records | |||

| Wave pattern of cycle | Abnormal cycle/Abnormal cycle+ previous cycle | ||

| /Every cycle/Arbitraly cycle | |||

| Maximum 32 cycles record | |||

| I/F | Outernal monitor | DC 0~5V×1 | |

| I/F for data management | RS232C、LAN | ||

| I/F for measured machine | OUT 6 terminals | Ready/Warning of main pattern/Warning of sub pattern | |

| /Overall NG/Start of cutting/ Finish of pattern change | |||

| IN 8 terminals | Pattern 4 terminals(16patterns)/Reset/Trigger/ | ||

| Neglecting judge/Outernal machine abnormity | |||

| LDC display(with touch-panel function) | 5.7inch Monocrome LDC(320×240dots) | ||

| Other function | Trigger delay/Smoothing/Scaling/Offset | ||

| /Neglected NG level /Neglected NG time | |||

| Internal pattern circulation/2 pattern judging | |||

| Supplementary items | Operation manual/Data acquisition software/ | ||

| Attaching parts set(Handy type does't involve.) | |||

| Option | CT(Current Transformer)/Harness for other than 200V | ||

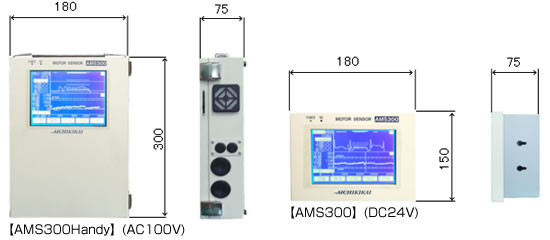

【Dimension】