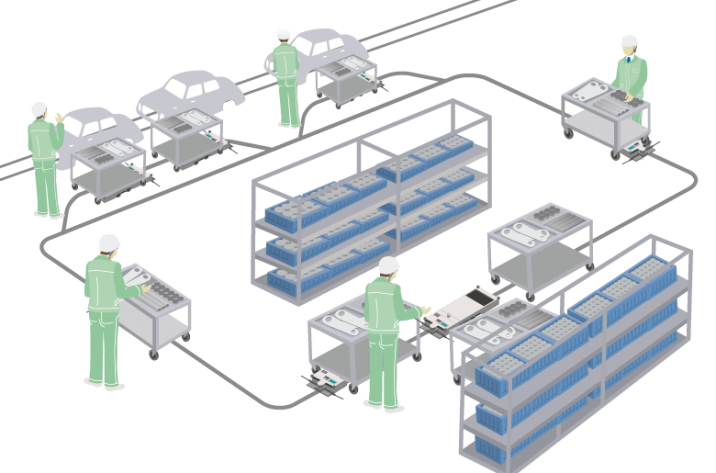

・ Avail the space effectively why it does not divide the workplace unlike hitherto known, fixed conveyer line.

・Makes it possible operations from all directions by setting the work on the AGV.

・Could swiftly modify the layout only by reset of the tape.

Modify the conveyer line to an AGV line

The points to streamline

Commonly-used processes

・Sub-line of instrument panel, engine, suspension in automotive production.

CarryBee is an unmanned carrier system which can rationalize conveyance between processes, parts supply to production lines and cellular manufacturing (assembly on AGV).

| Dolly Type | |||

|---|---|---|---|

| Low Height Type | |||

| Other Type | |||

| Option & Accessories | Customized Type | ||