HOMEAGVs for water environments

AGVs for water environments

Transportation between factory buildings, food factories, and school lunch centers

4 reasons to choose

Proposal Ability

As a manufacturer specializing in AGVs, we have a track record of proposing and delivering many systems.

Optimization

Taking advantage of the strengths of the AGV manufacturer, we can provide optimal customization.

Improvement Ability

Our parent company is an engine manufacturer, so our process improvement skills are possible

Support

We provide comprehensive support from the planning stage through to post-delivery maintenance and service.

If you need an AGV that can handle water environments, leave it to Aichi Machine Techno System.

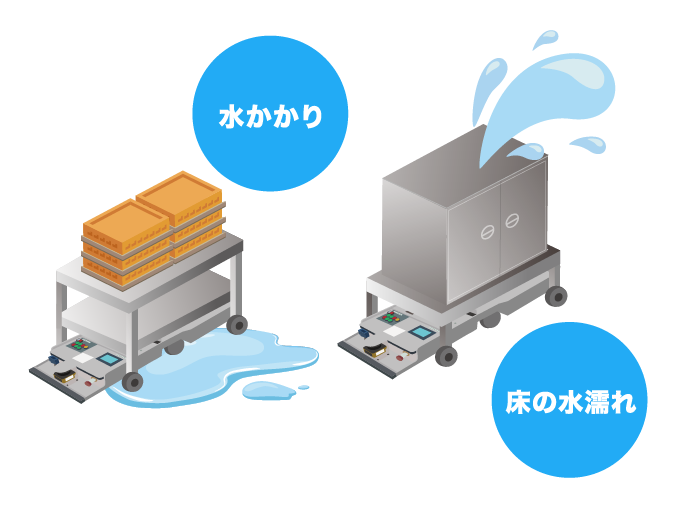

The environment for unmanned transport in food factories is different from other manufacturing plants.

It is necessary to prevent rust from splashing water, protect the electrical systems,

and prevent slipping due to puddles on the floor.

In addition, the passageways near the work area are narrow and the AGV cannot reach its final destination,

so an effective method is to detach the AGV from the AGV and have the worker easily transport it to the destination.

There are many other characteristic environmental conditions,

and currently there are not many AGVs for food factories, but in the future it is expected that there will be more that are suited to the on-site environment and needs.

Autonomous transport in food factories

An example of manual transport commonly seen in food factories is thermal containers for school lunches. Some weigh nearly 500 kg, so automation is desirable in order to reduce the amount of heavy physical labor involved. Stacked food containers are placed on a dolly cart and transported by hand. Even with automated transport, they need to be transported on the dolly cart near the work area so that they can be moved freely by hand. Both carts have four swivel wheels, so if they are transported by AGV, normal towing methods cannot be used and some ingenuity is required.

Frequently seen transportation

An example of manual transport commonly seen in food factories is thermal containers for school lunches. Some weigh nearly 500 kg, so automation is desirable in order to reduce the amount of heavy physical labor involved. Stacked food containers are placed on a dolly cart and transported by hand. Even with automated transport, they need to be transported on the dolly cart near the work area so that they can be moved freely by hand. Both carts have four swivel wheels, so if they are transported by AGV, normal towing methods cannot be used and some ingenuity is required.

Transportation issues in food factories

In addition to the water-related issues mentioned above, transportation issues in food factories are diverse, including foreign matter contamination, high-mix low-volume production, unstable production due to seasonal fluctuations, and temperature environments. We have released a model that is compatible with water environments, but we believe that customers have other unique conditions. We specialize in AGVs and are good at custom specifications, so we would be happy to hear about your issues.

Recommended AGVs

AGV type Dolly trolley Various trolleys Transportation in food factories and school lunch centers Cart Series Waterproof Series

DB waterproof type

This AGV can withstand wet conditions and wet roads, such as in food factories and transport between buildings. It tows and transports carts loaded with food containers, etc. The carts are automatically connected and disconnected.

Automate manual tasks with mobile robots!!

AGVs for water environmentsFor inquiries and consultations, please click here

If you are interested in AGVs for water environments, please fill out the form below and submit.

* indicates required fields.