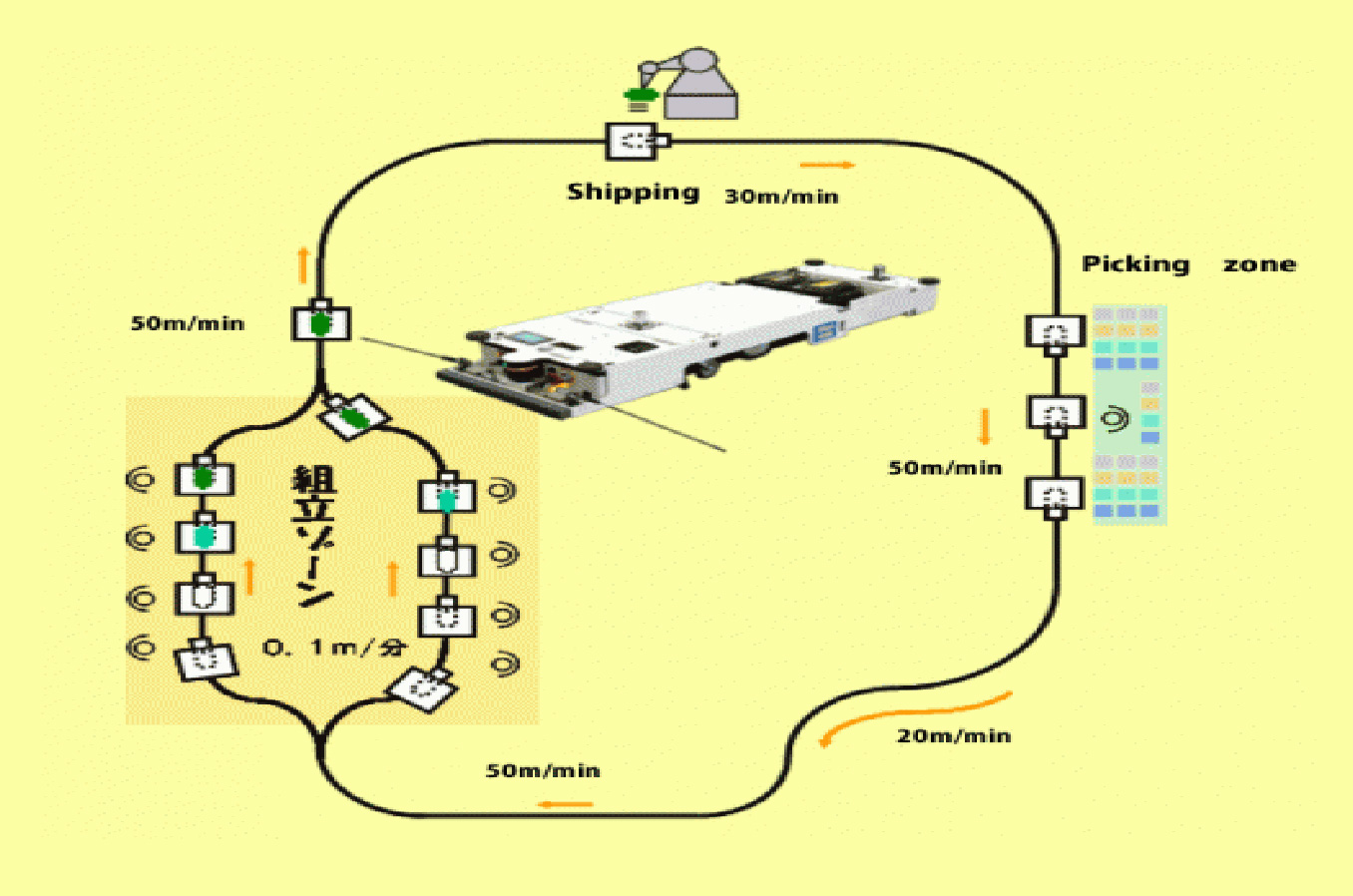

Assembly lines using AGVs are on the rise

Assembly lines that use ultra-low speed (0.1m/min to 50m/min) running performance are on the rise.

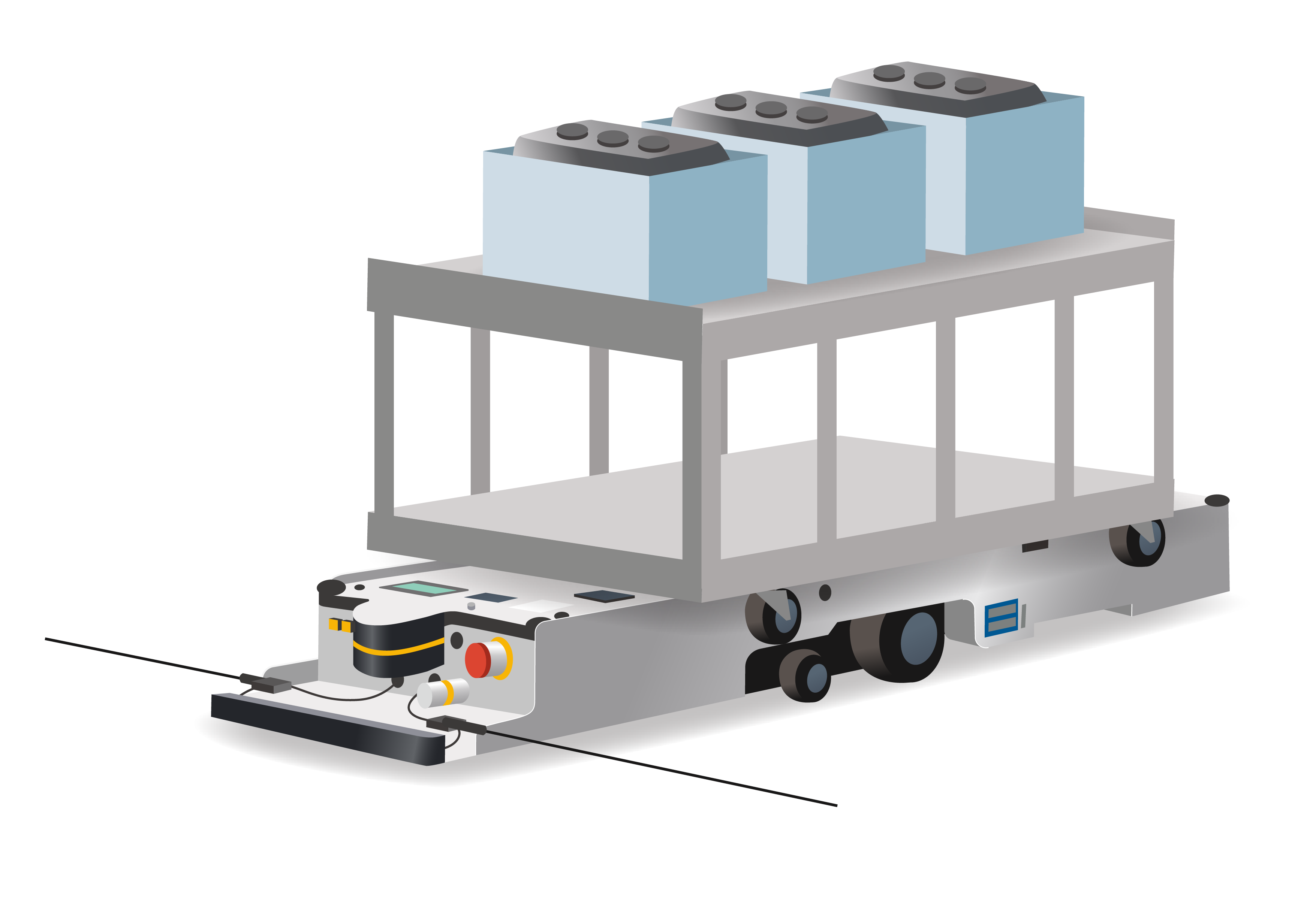

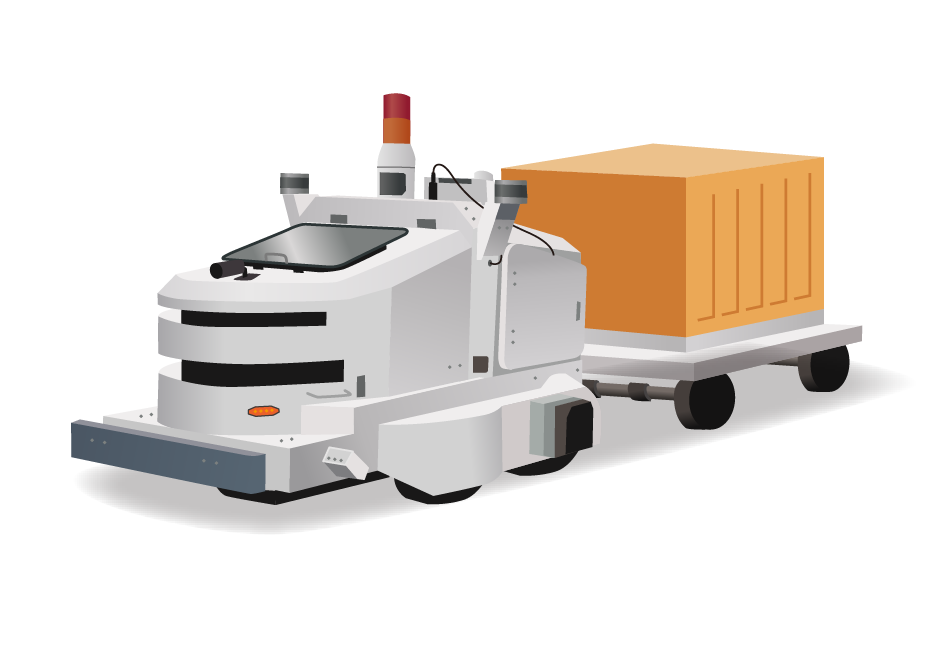

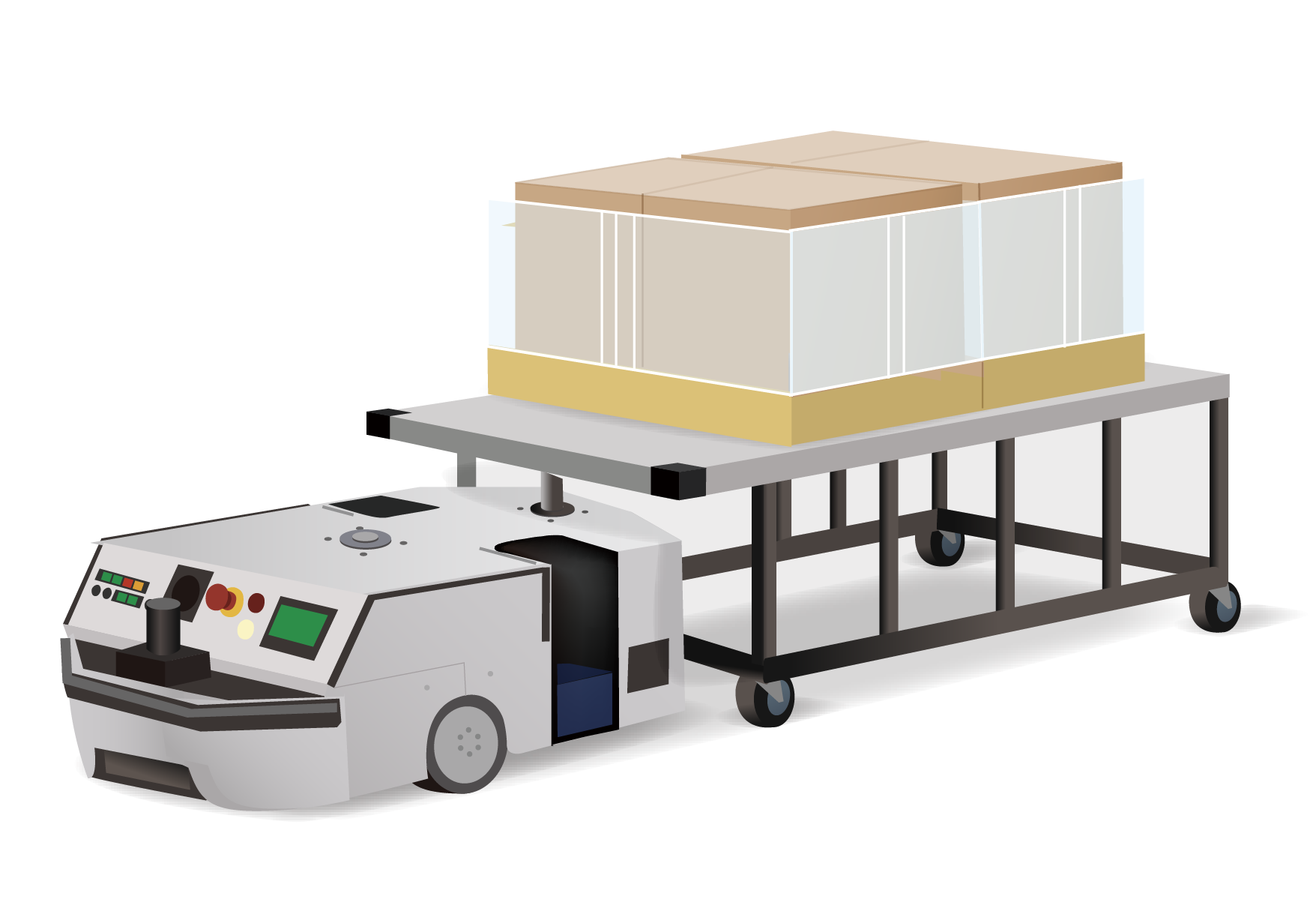

Flexible AGV line

– No fixed objects that divide space like conveyor lines are required.

– Since there is no conveyor, assembly work can be done from any direction.

– The line can be changed simply by replacing the running tape.

– Line length and number of processes can be easily increased or decreased depending on production volume.

– By changing the assembly work cart, different products can be assembled even if they are different sizes.

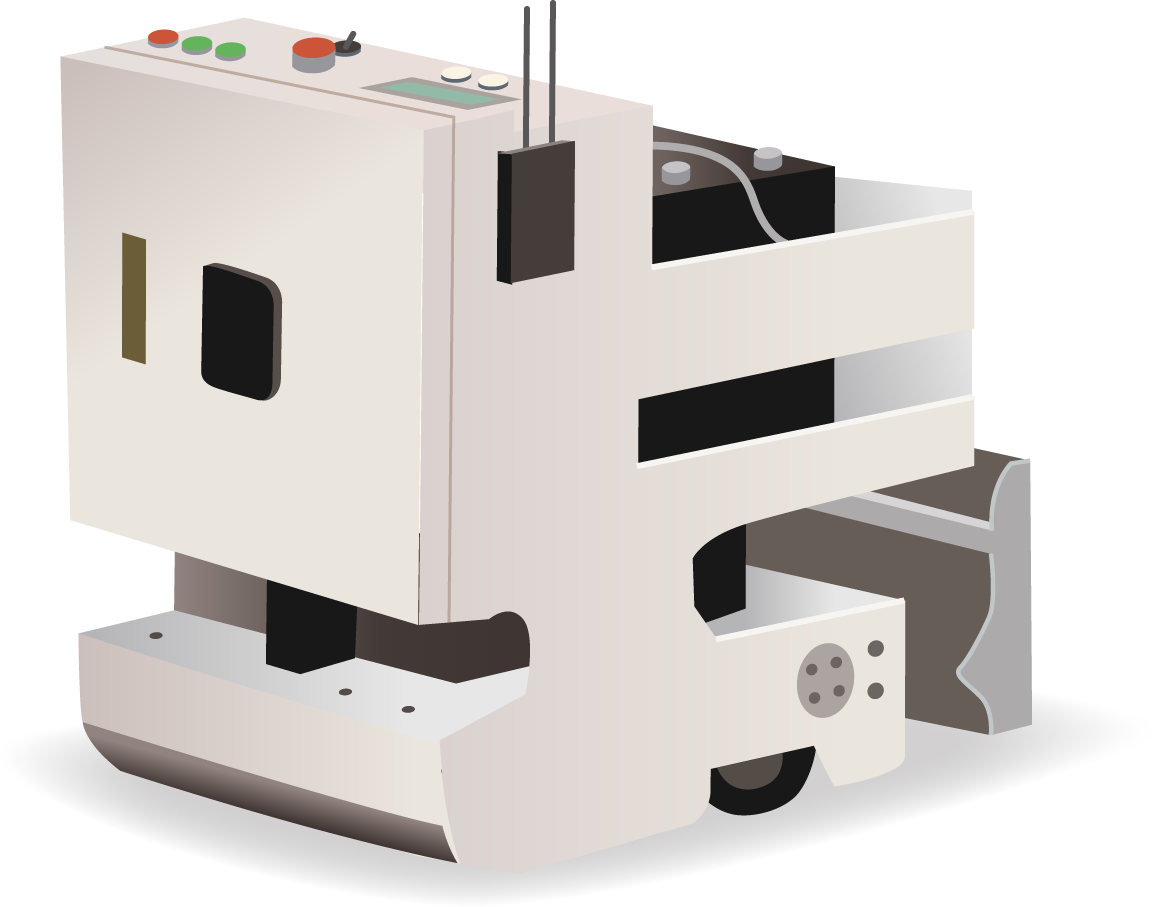

Why ultra-low speed types are suitable

If ultra-low speed is not possible, it is necessary to stop the AGV during work. In that case, the following problems arise.

– The AGV is started by pressing a button after the work is completed, so the production tact is left to the worker.

– Assembly work cannot be done while the AGV is running between processes, so time is lost.