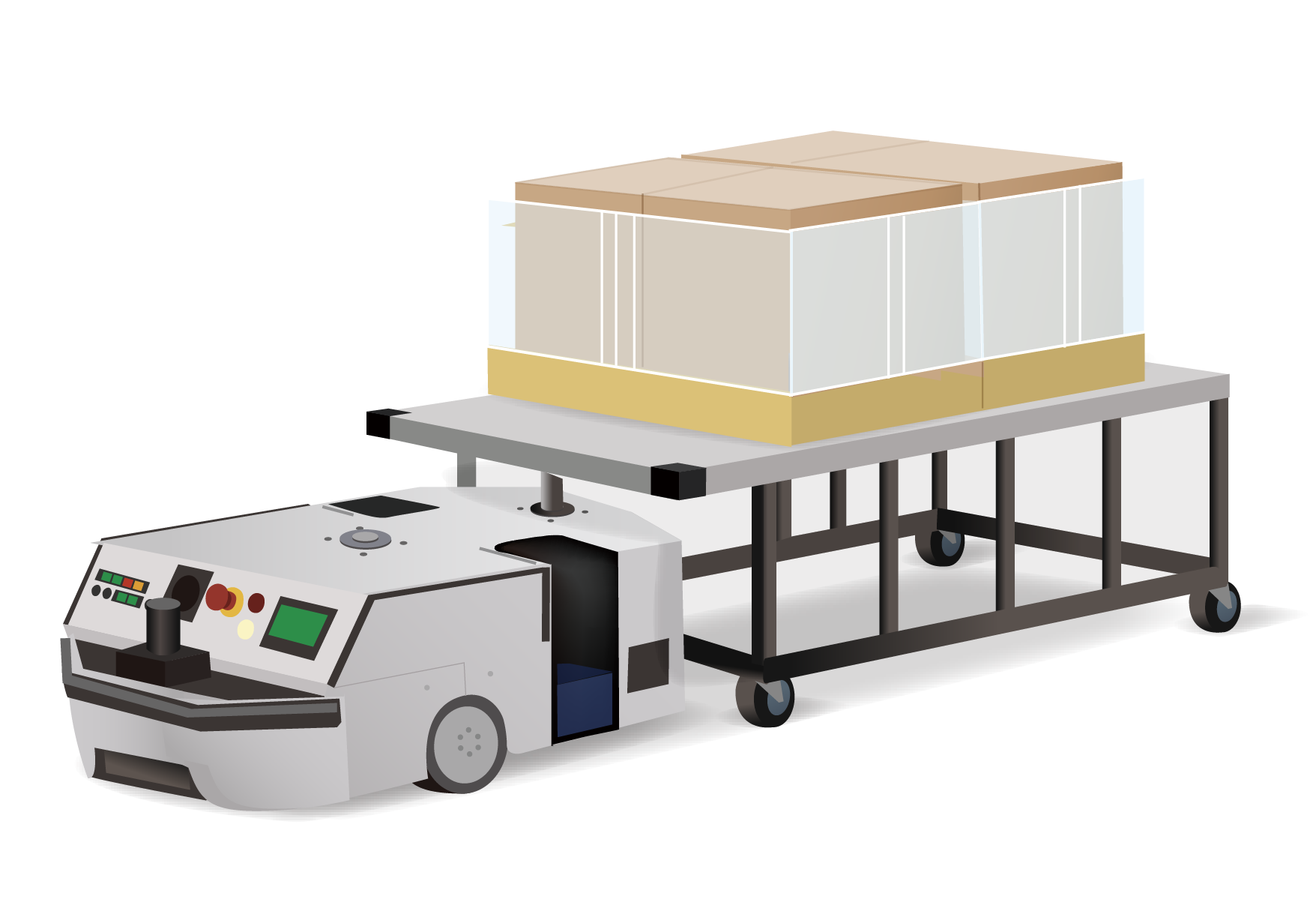

Transporting basket trolleys

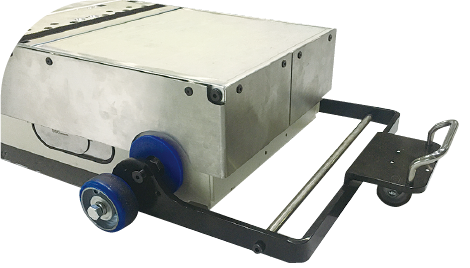

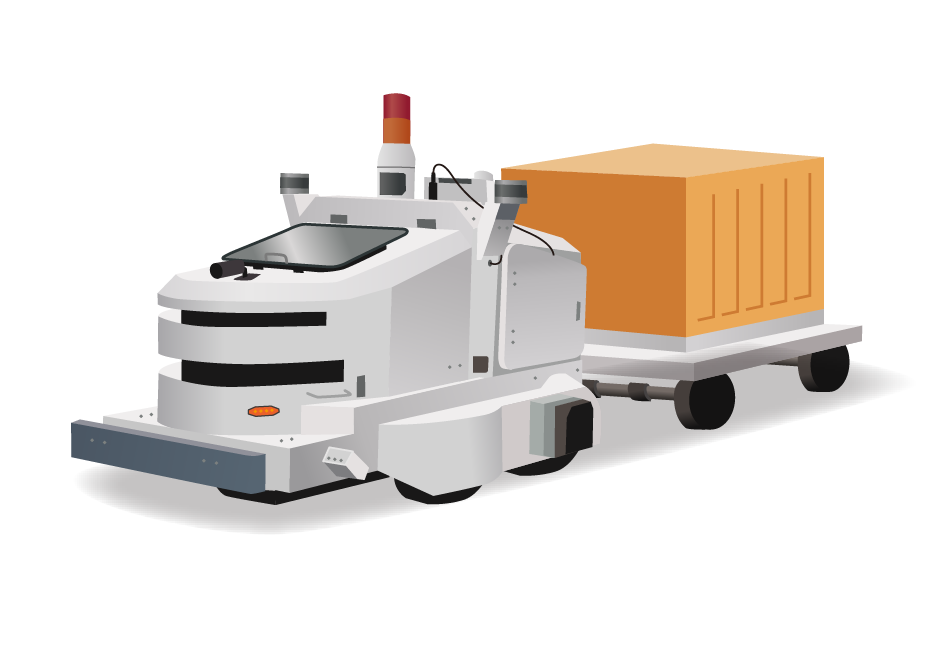

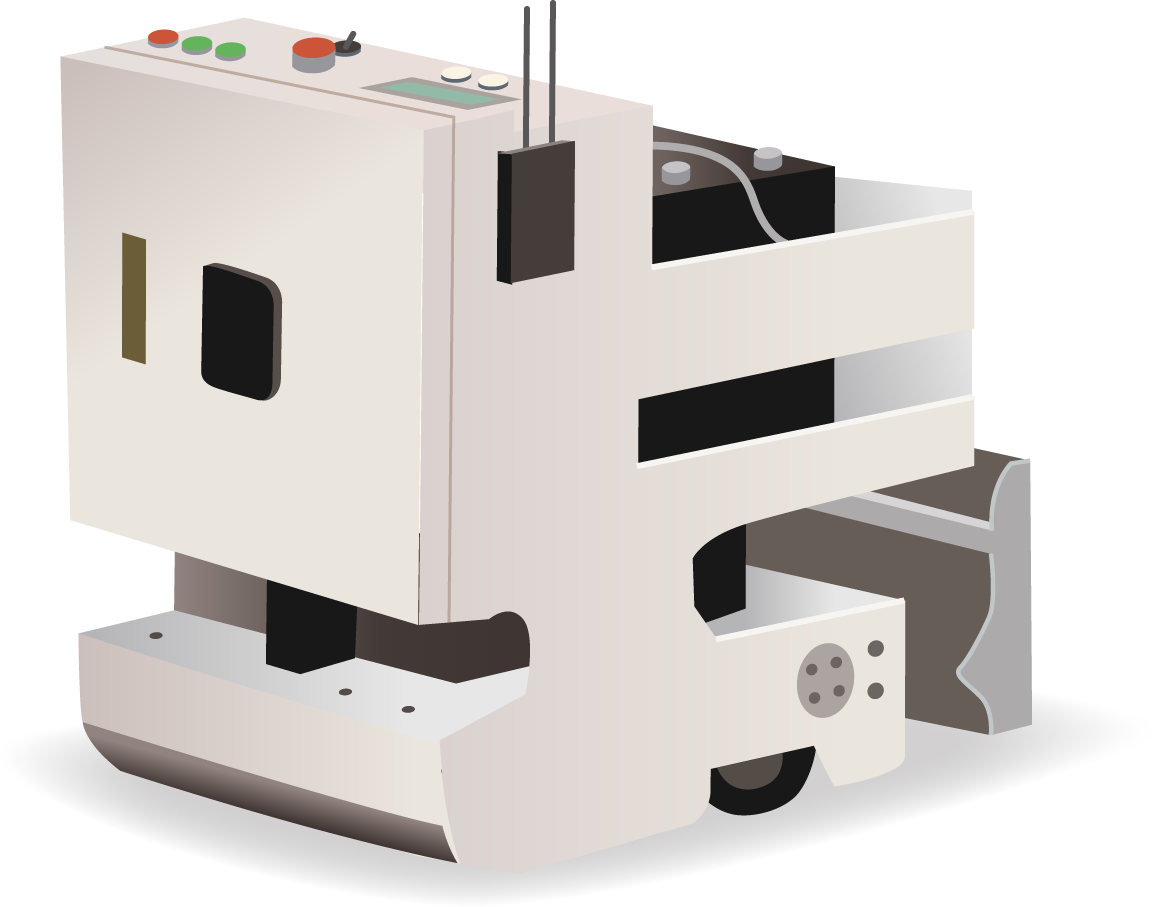

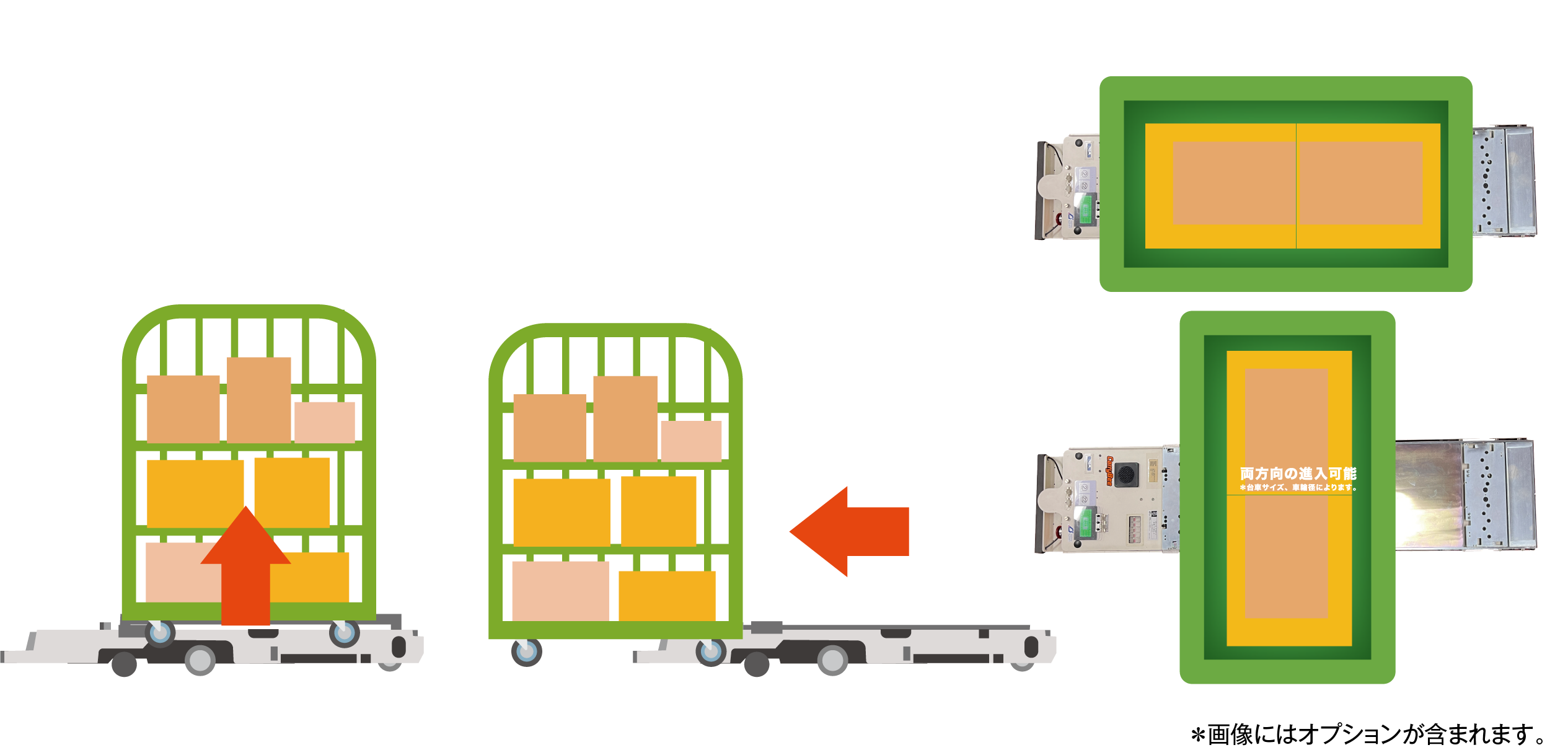

● Enters under the trolley and lifts it up for transport.

● Compatible with 1100 x 800 and 800 x 600 size trolleys.

Lifts up the framework at the front and rear ends of the trolley. No modification of the trolley is required.

Because it is a type that enters, trolleys can be arranged vertically.

Can enter in both directions *Depends on the trolley size and wheel diameter.

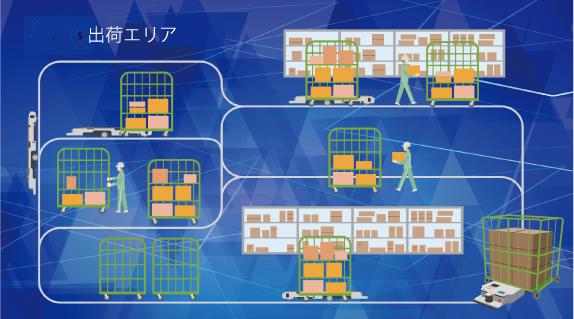

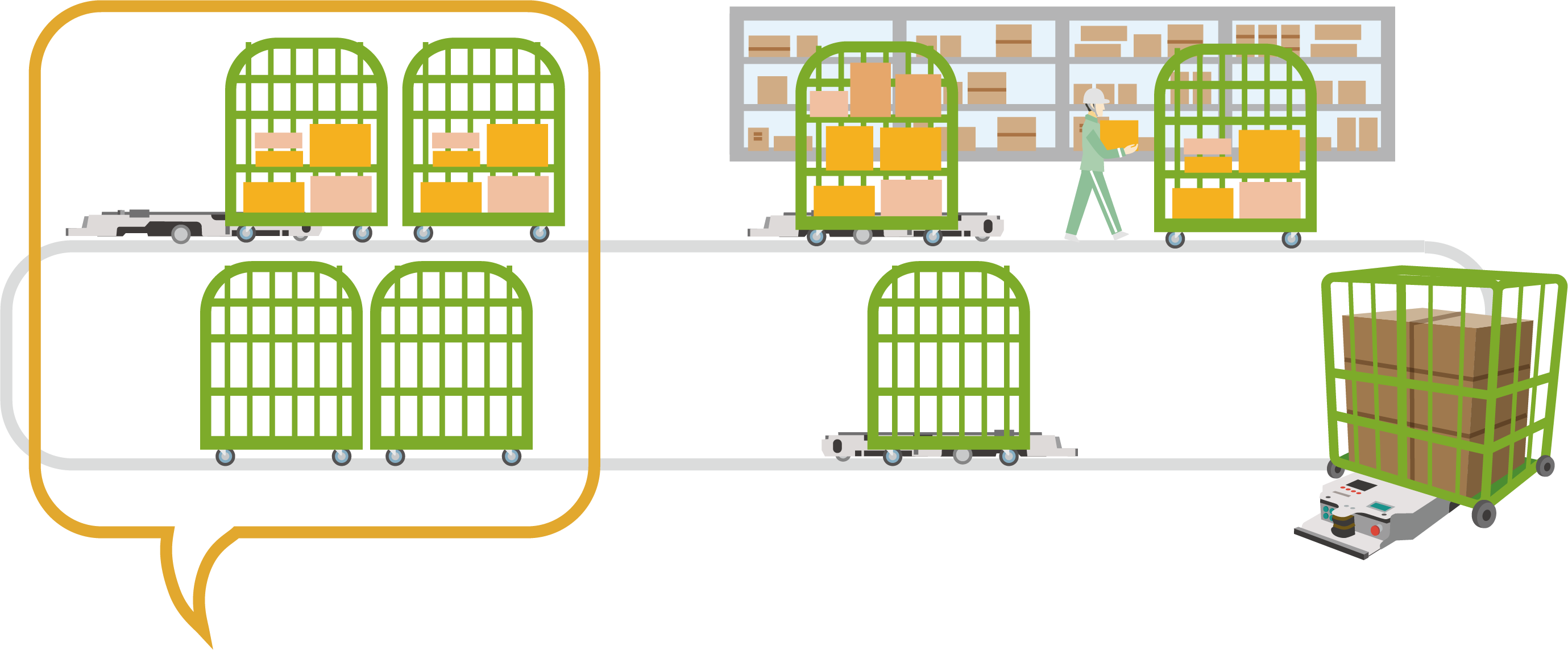

Use Case

Automate transportation from the storage area of the logistics center to the shipping area

●Pick up products in the storage area and load them onto a basket cart.

●The AGV transports them to the shipping area and arranges them in a line.

●The AGV lifts up the leading empty cart lined up in a separate lane.

●The empty cart is transported to the storage area and placed in the designated location.

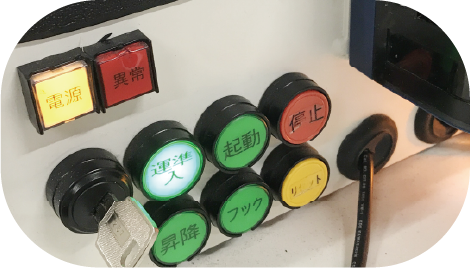

Options

●Indicator light (signal tower)●Melody unit●Mechanical switch●Battery●Charger (manual)●Automatic charger●Beard sensor

●Motor brake●Wireless between AGVs●Integrated control (AGV wireless control)●Optical communication●Remote control●Tablet operation●Program transfer software etc.

2023 Smart Factory EXPO