HOMERobot Station RST

Reasons for choosing the robot package

Proposal Ability

As a manufacturer specializing in AGVs, we have a track record of proposing and delivering many systems.

Optimization

Taking advantage of the strengths of the AGV manufacturer, we can provide optimal customization.

Improvement Ability

Our parent company is an engine manufacturer, so our process improvement skills are possible

Support

We provide comprehensive support from the planning stage through to post-delivery maintenance and service.

AGV and robot package!

The Robot Station combines a robot with an AGV to achieve automation that is closer to human work.

For example, a collaborative robot can be made into a station. The station can then be transported by an AGV,

or the AGV can transport parts to the robot, which then handles them. Depending on the combination, various streamlining possibilities are possible.

Below are some examples of how the Robot Station is used.

CarryBee Robot Package

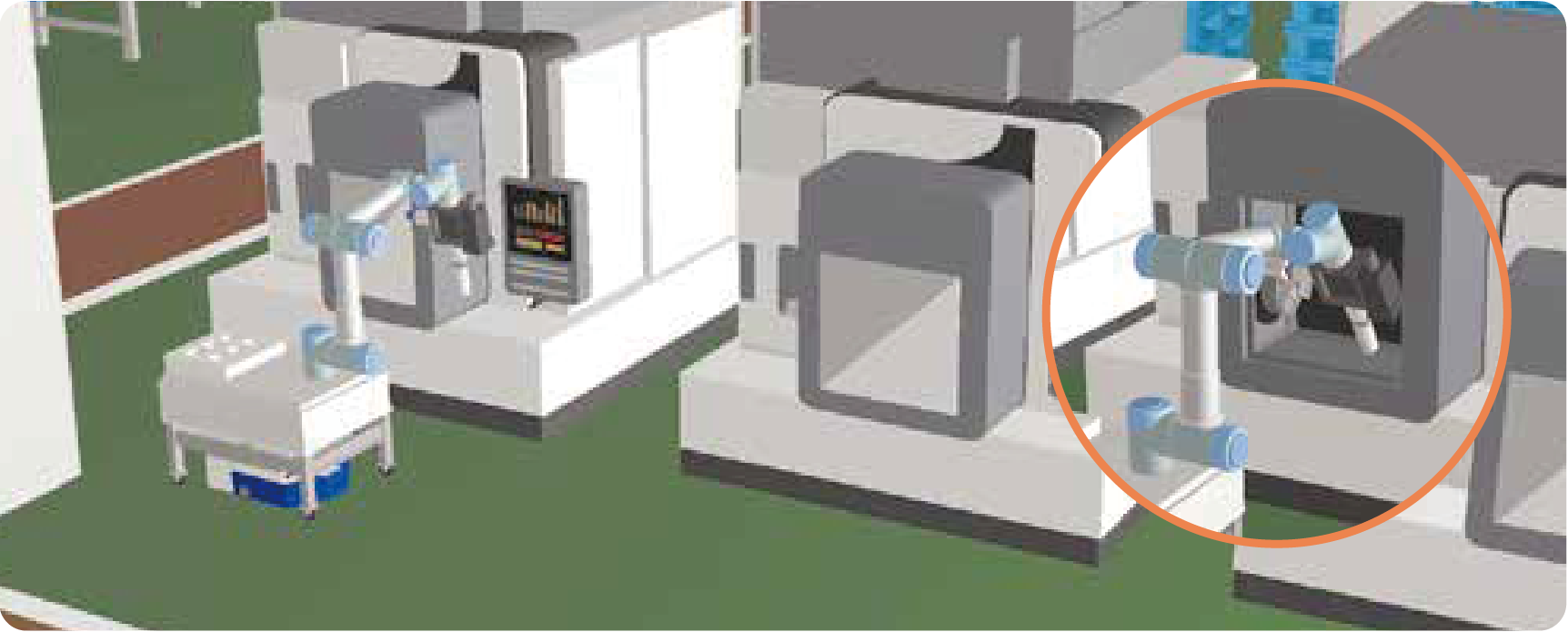

CASE1Production: Automating workpiece changes in machining

Automate machine tending, including material loading and replacement

The robot replaces the workpiece and the AGV moves the robot. This reduces repetitive manual work and improves machine operation rate by moving the robot, while also improving safety.

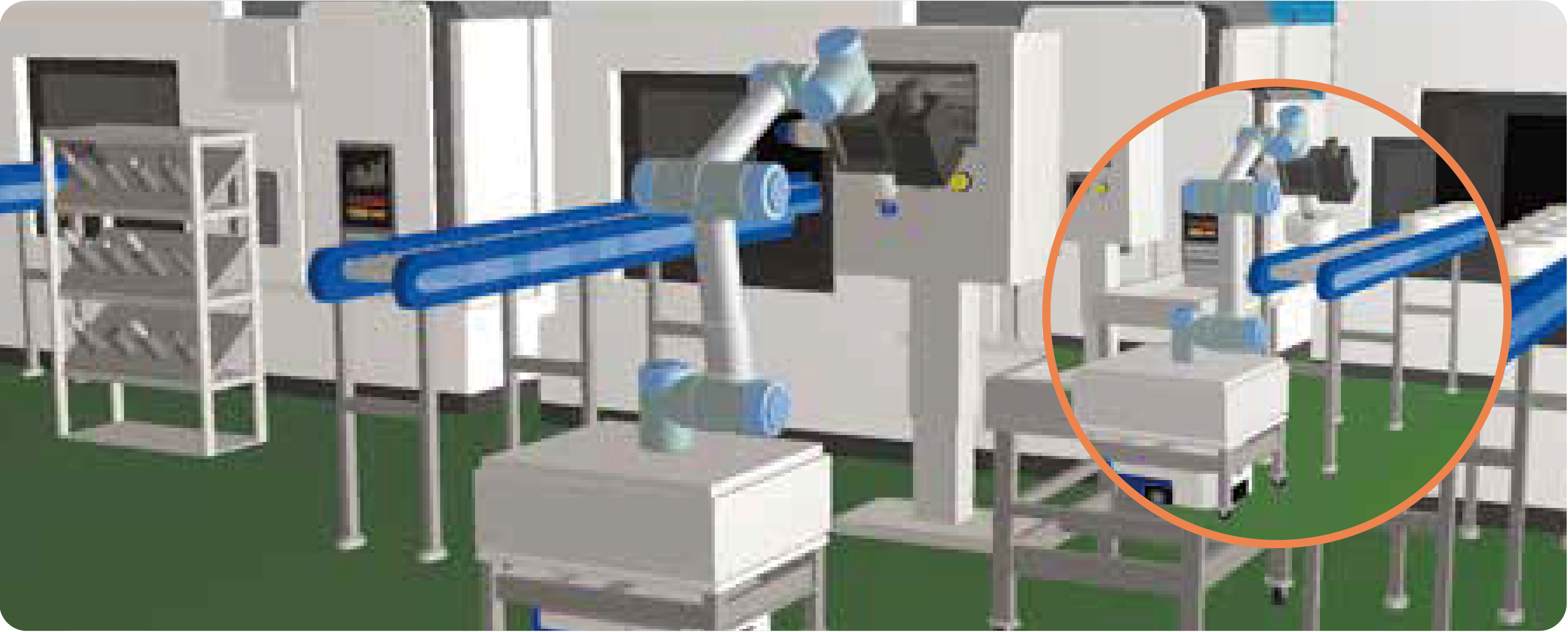

CASE2Production: Putting parts into the processing machine

Automate the transportation of parts to multiple processing machines and the input of parts into the processing machines

The robot inserts the parts and the AGV moves the robot.

Recommended AGVs

AGV type Various trolleys Low Floor Series Low Floor Series

Low floor M type

It is possible to load a trolley, and it can be automatically coupled and detached.

This is the standard type that is most versatile in the low-floor series.

AGV type Various trolleys Low Floor Series Low Floor Series

Low floor S type

It can slip under the cart and tow, automatically couple and detach.

The most compact of the low-floor series, ideal for transporting small parts.

CASE3Production: Robot assembly on AGV line

AGVs form an assembly line, and robots assemble

The AGV advances the work carts in sequence, and the robot assembles them. This enables a flexible assembly line that can be reorganized. This eliminates the division of work areas by conveyors, and enables the automation of assembly work.

Recommended AGVs

AGV type Various trolleys Low Floor Series Low Floor Series

Low floor M type

It is possible to load a trolley, and it can be automatically coupled and detached.

This is the standard type that is most versatile in the low-floor series.

AGV type palette Eight Series Eight Series

Eight Plus

This transports carts loaded with pallets.

It is used for transporting between storage areas and work processes on the line, and for transporting to the loading and unloading area.

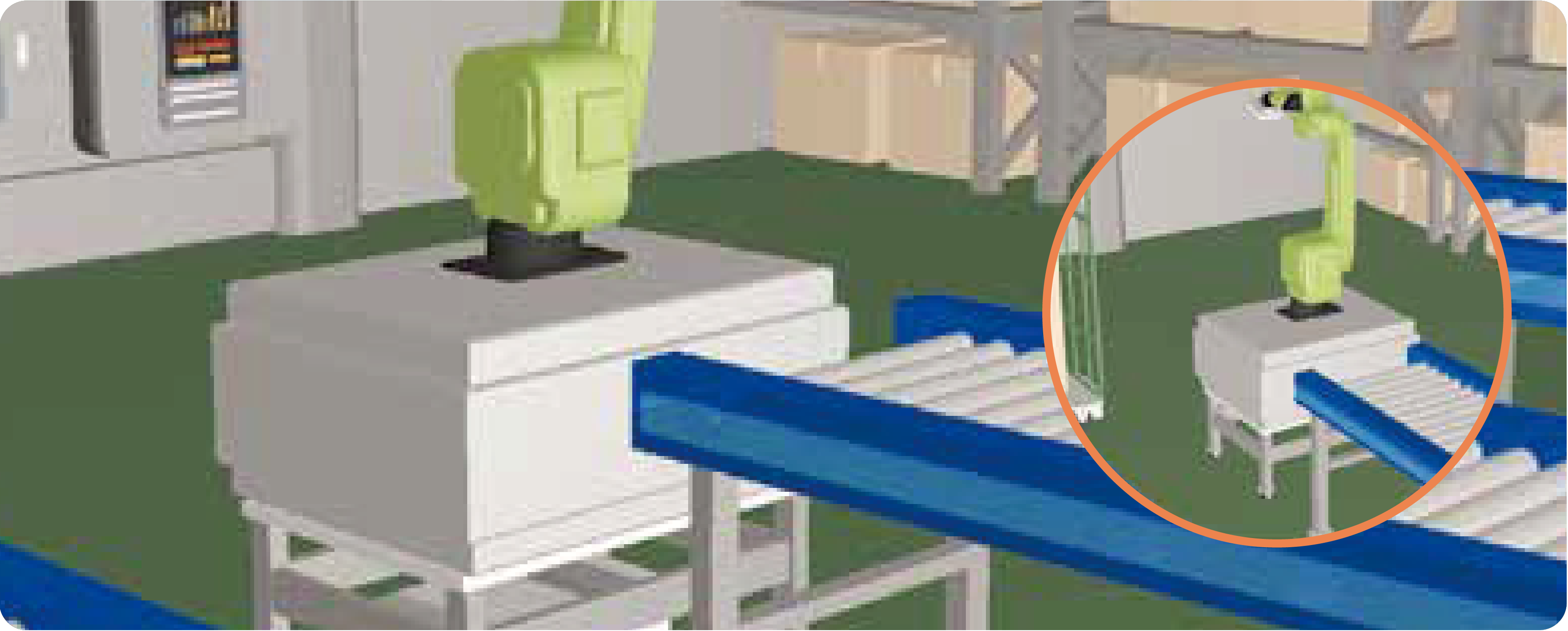

CASE4Logistics: Palletizing for shipping process

Automate manual palletizing and cart transport work

The robot loads the items and the AGV transports the cart. Reduces repetitive manual tasks and eliminates heavy physical labor! We will automate cart transportation.

Recommended AGVs

AGV type Basket trolley transport Various trolleys AGVs in automobile and other production factories Cart Type AGV solutions for logistics centers Cart Series

DB Type

A new towing hook mechanism automatically connects to the dolly.

We will manufacture a towing hook to suit your dolly.

CASE5Logistics: Moving robots and palletizing through multiple processes

The robot palletizes the items onto a basket cart, etc., and the cart is transported by the AGV.

The robot loads the items, and the AGV moves the robot! This reduces repetitive manual work and heavy physical labor, reduces the number of robots required, improves operation rates, and automates cart transport.

Recommended AGVs

AGV type palette Eight Series Eight Series

Eight Plus

This transports carts loaded with pallets.

It is used for transporting between storage areas and work processes on the line, and for transporting to the loading and unloading area.

AGV and robot package!

Robot Station RSTFor inquiries and consultations, please click here

If you are interested in the Robot Station RST, please fill out the form below and submit it.

* indicates required fields.