HOMELogistics AGV

4 reasons to choose

Proposal Ability

As a manufacturer specializing in AGVs, we have a track record of proposing and delivering many systems.

Optimization

Taking advantage of the strengths of the AGV manufacturer, we can provide optimal customization.

Improvement Ability

Our parent company is an engine manufacturer, so our process improvement skills are possible

Support

We provide comprehensive support from the planning stage through to post-delivery maintenance and service.

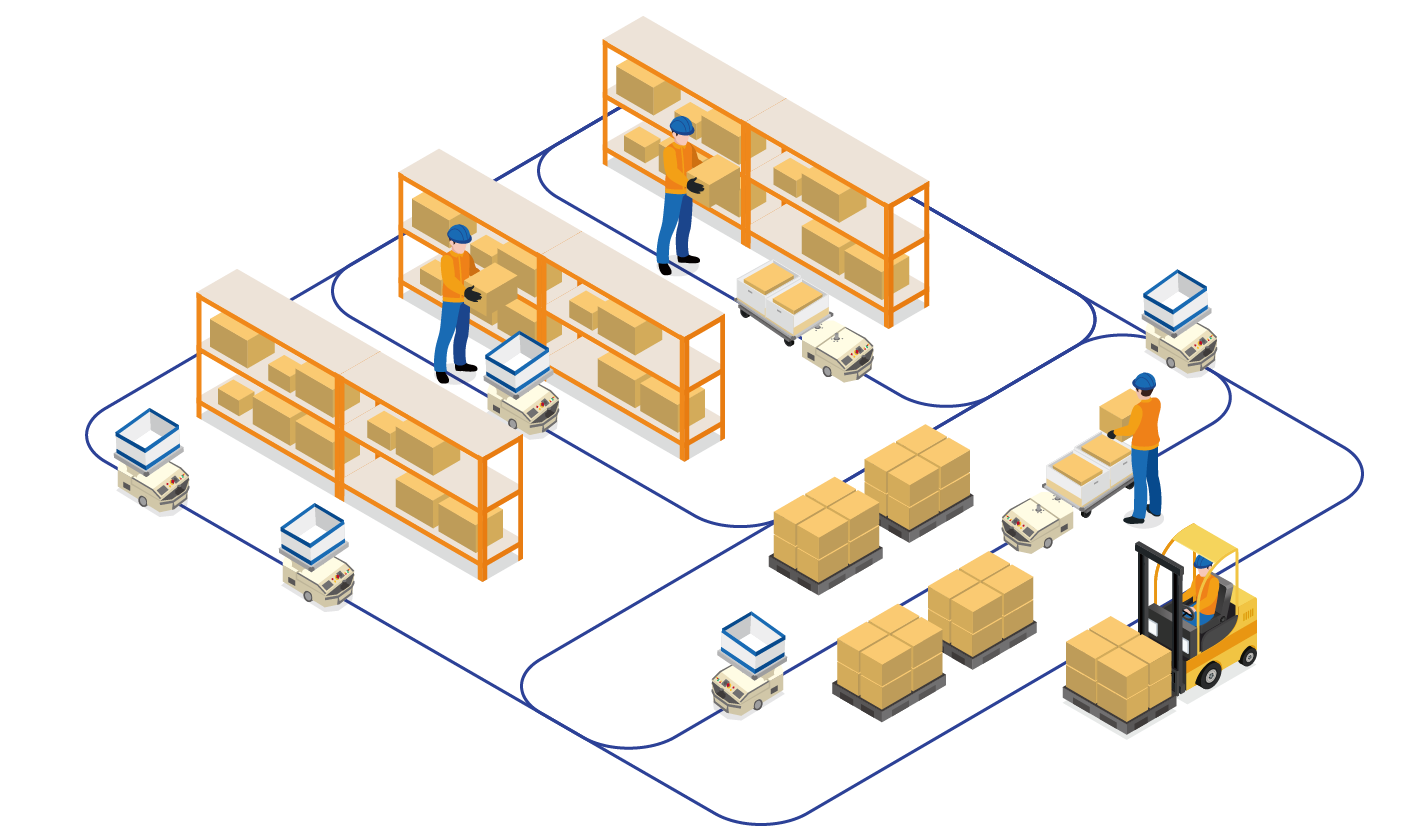

If you need AGVs for your logistics center, leave it to Aichi Machine Techno System.

The environment for unmanned transport in food factories is different from other manufacturing plants.

It is necessary to prevent rust from splashing water, protect the electrical systems, and prevent slipping due to puddles on the floor.

In addition, the passageways near the work area are narrow and the AGV cannot reach its final destination, so an effective method is to detach the AGV from the AGV and have the worker easily transport it to the destination.

There are many other characteristic environmental conditions, and currently there are not many AGVs for food factories, but in the future it is expected that there will be more that are suited to the on-site environment and needs.

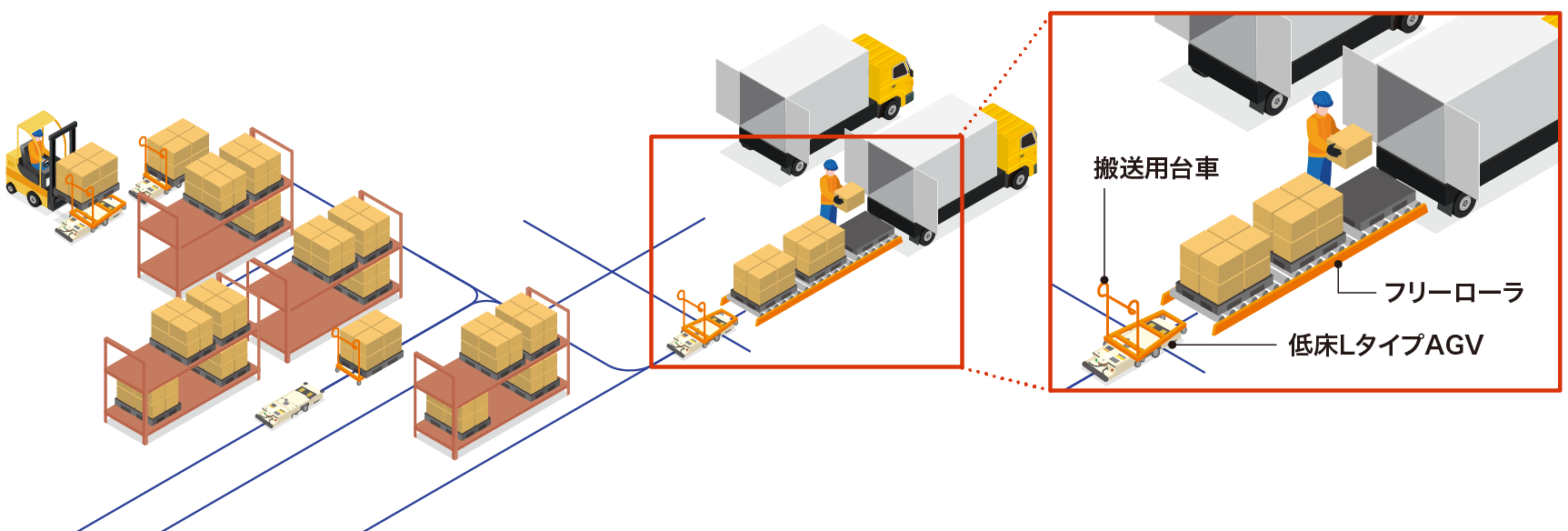

CASE 1Automatically connects and transports pallets after debunking

Instead of line-side assembly workers selecting parts, the parts for one product are set outside the line and supplied to the assembly line. This has the advantages of reducing part assembly errors, shortening assembly cycle times, and reducing the number of parts on the line.

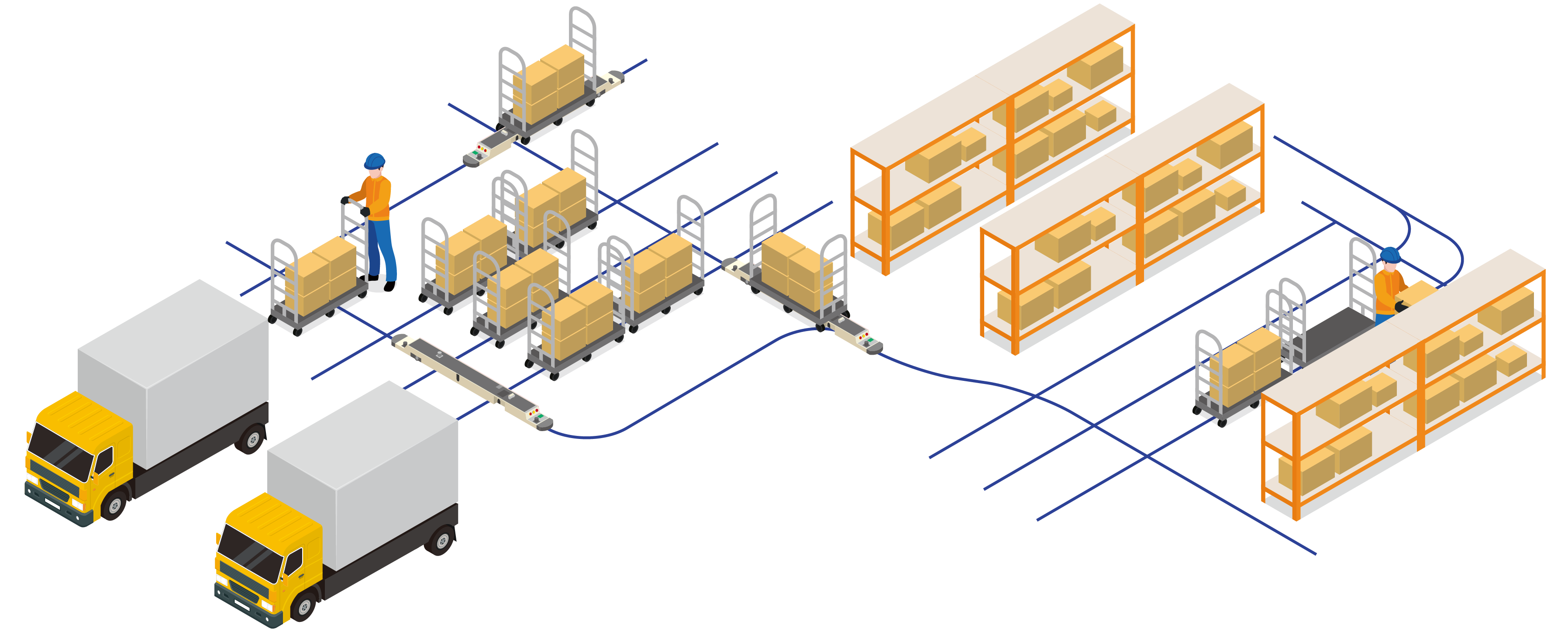

CASE 26-wheeled trolley transport

The ultra-slim Dragon3 slides under the six-wheeled trolley, lifting up the front end of the trolley and transporting the goods. In the storage area, the goods are loaded onto the trolley and transported to the shipping area. At the destination, the six-wheeled trolleys are arranged in a vertical line. The trolley is detached at the end of the line, and the AGV reverses from that position to arrange the goods in a vertical line.

Recommended AGVs

AGV type 6-wheel trolley transport Dragon Series Dragon Series

Dragon3

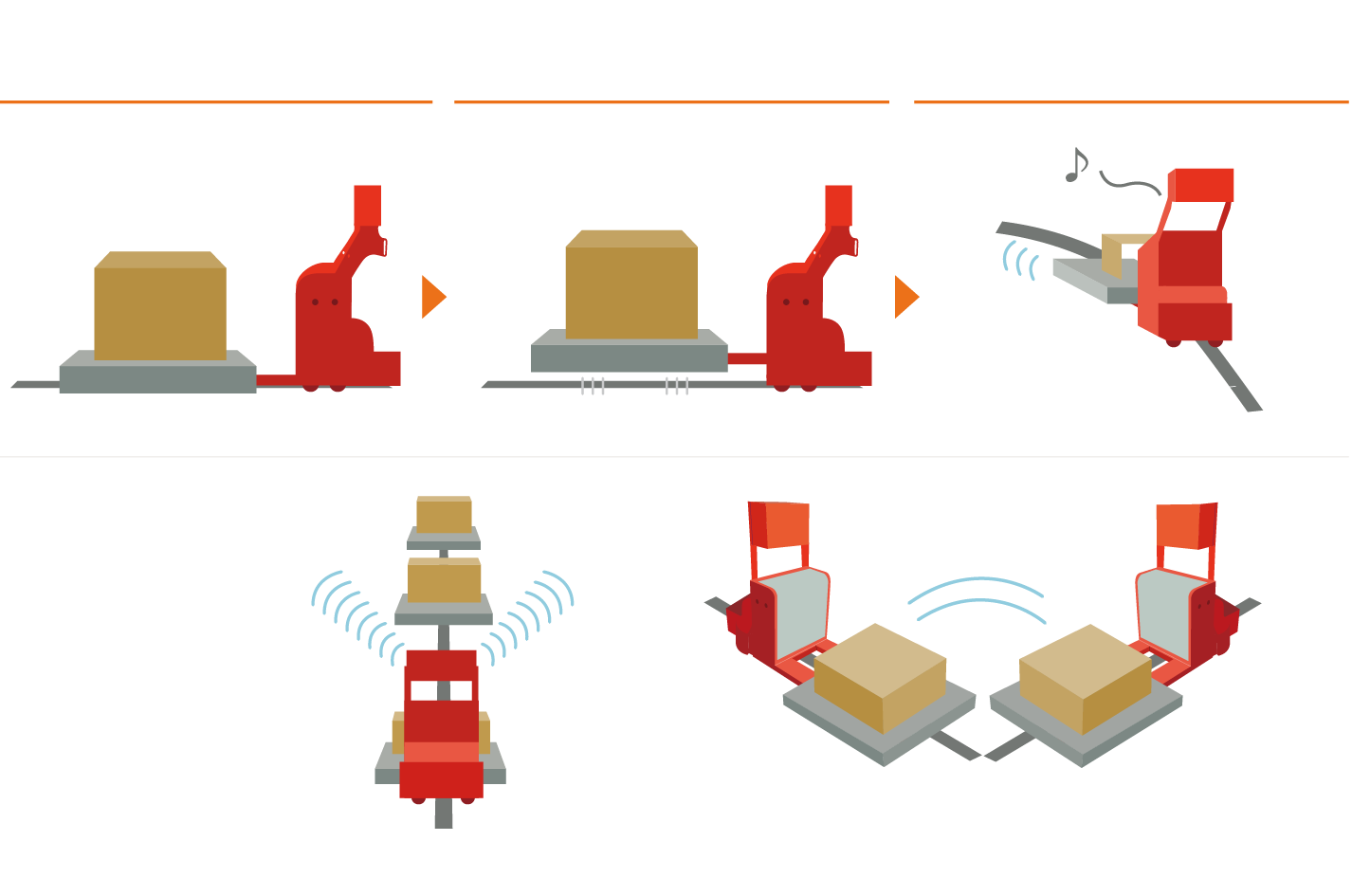

It transports 6-rin dollies, which are often used in logistics centers.

It slides under the dolly and automatically couples and detaches it.

It can align the dollies at the destination.

AGV type 6-wheel trolley transport Dragon Series Dragon Series

Dragon1

This system transports wide 6-wheel carts. If you need to transport standard 6-wheel carts with a width of 420 mm, please consider the Dragon 3.

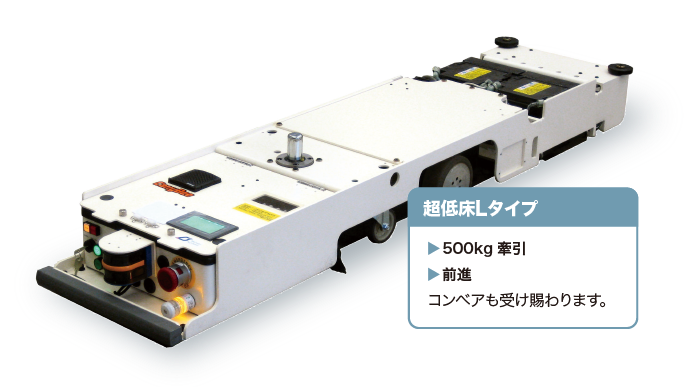

AGV type Various trolleys Low Floor Series Low Floor Series

Low floor L type

- Suitable for cases where the gap between the bottom of the towing dolly and the floor is narrow

- Transport weight: 500 kg for forward travel and 750 kg for forward/reverse travel

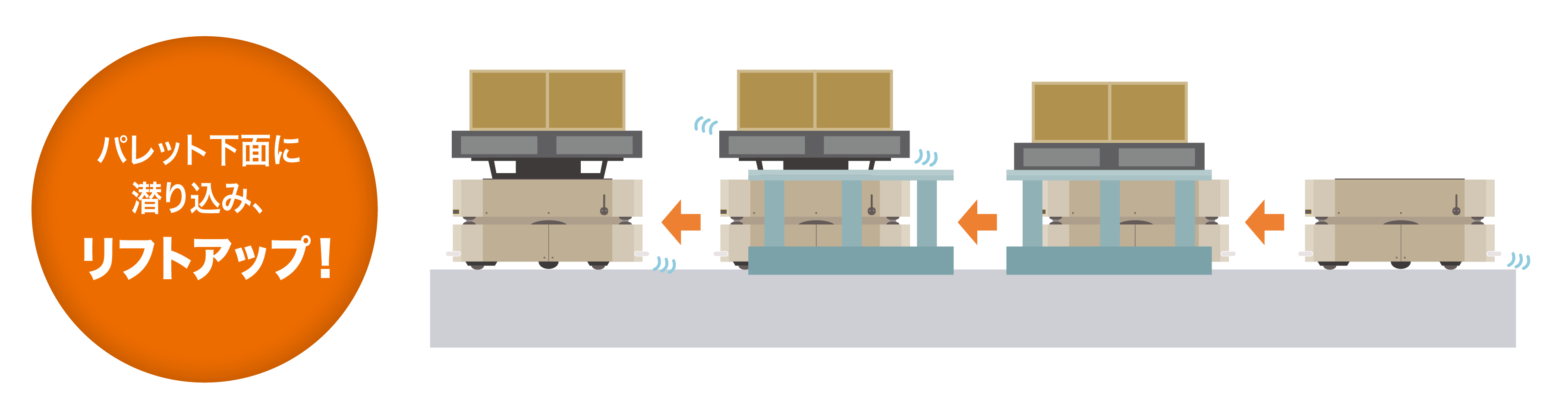

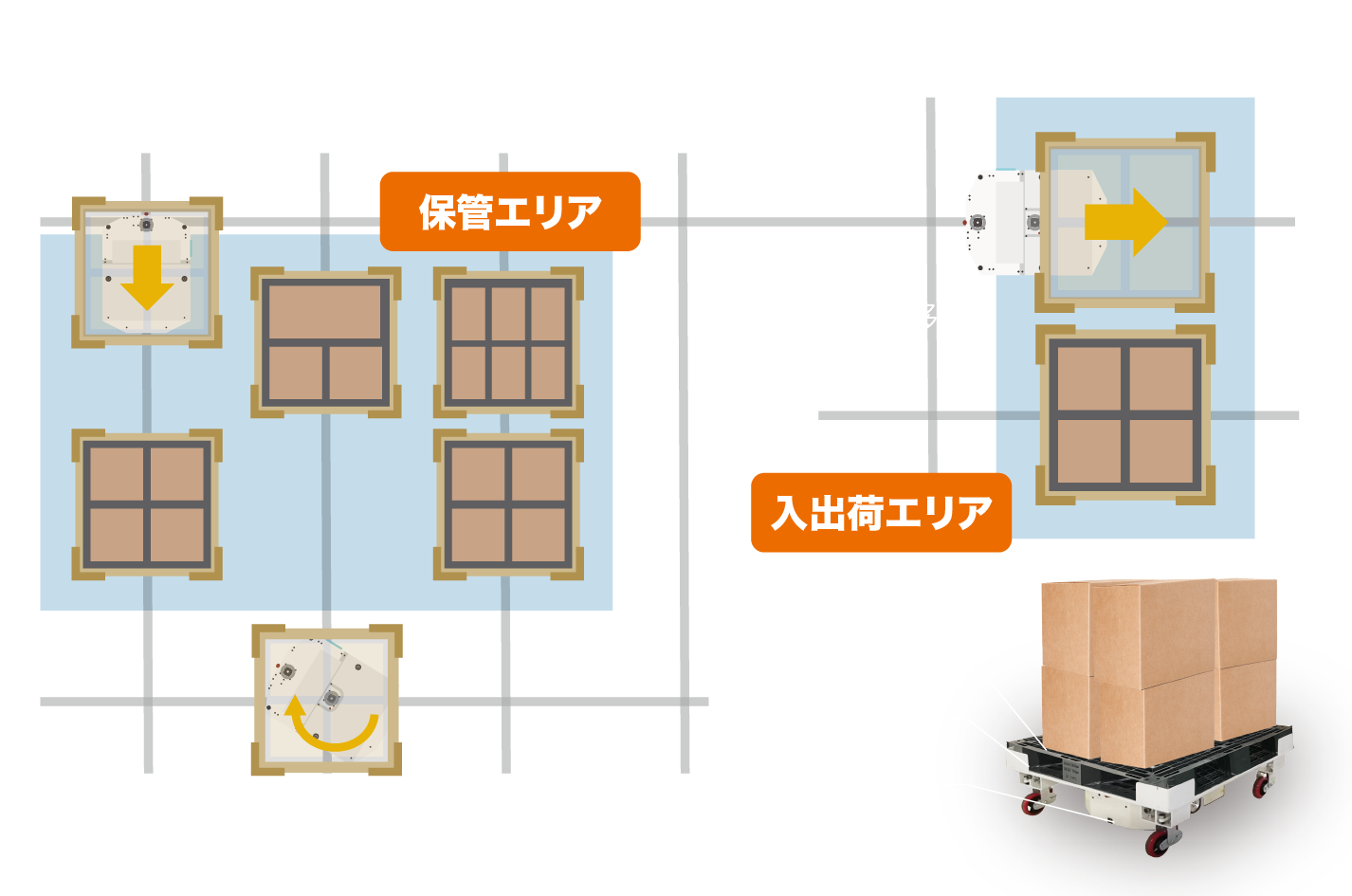

CASE3Pallet transport

Lifts up and transports pallets on the station (pallet placement stand) or conveyor

The ultra-slim Dragon3 slides under the six-wheeled trolley, lifting up the front end of the trolley for transport. In the storage area, the products are loaded onto the trolley and transported to the shipping area. At the destination, the six-wheeled trolleys are arranged in a vertical line. The trolley is detached at the end of the line, and the AGV reverses from that position to arrange the products in a vertical line.

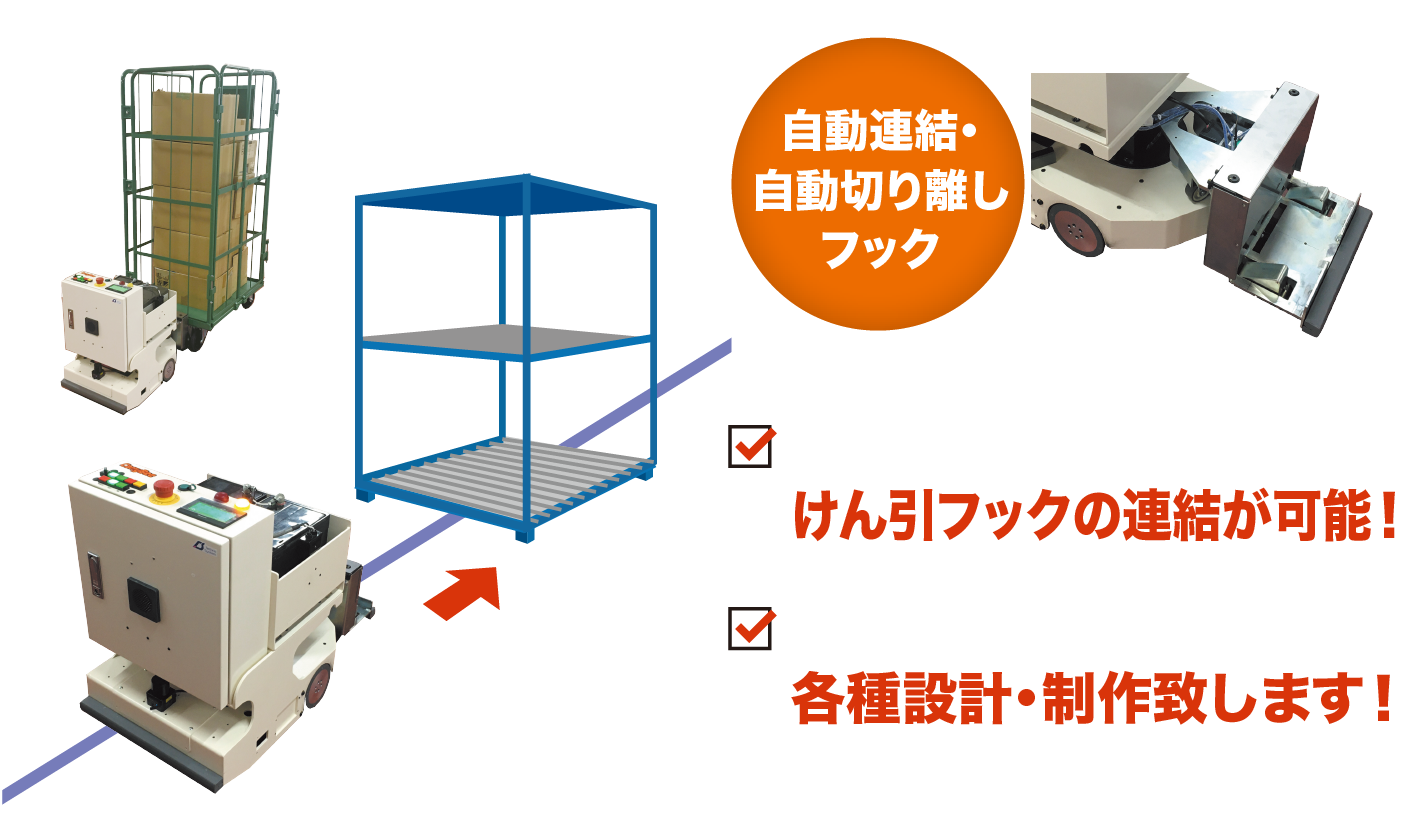

Towing a pallet transport cart

Products are stored on pallets mounted on a transport cart. Eight Plus slides under the cart and automatically connects to it for transport. The AGV alone rotates 90 degrees and 180 degrees under the cart, allowing the cart to move at right angles.

Pallet transport at low cost

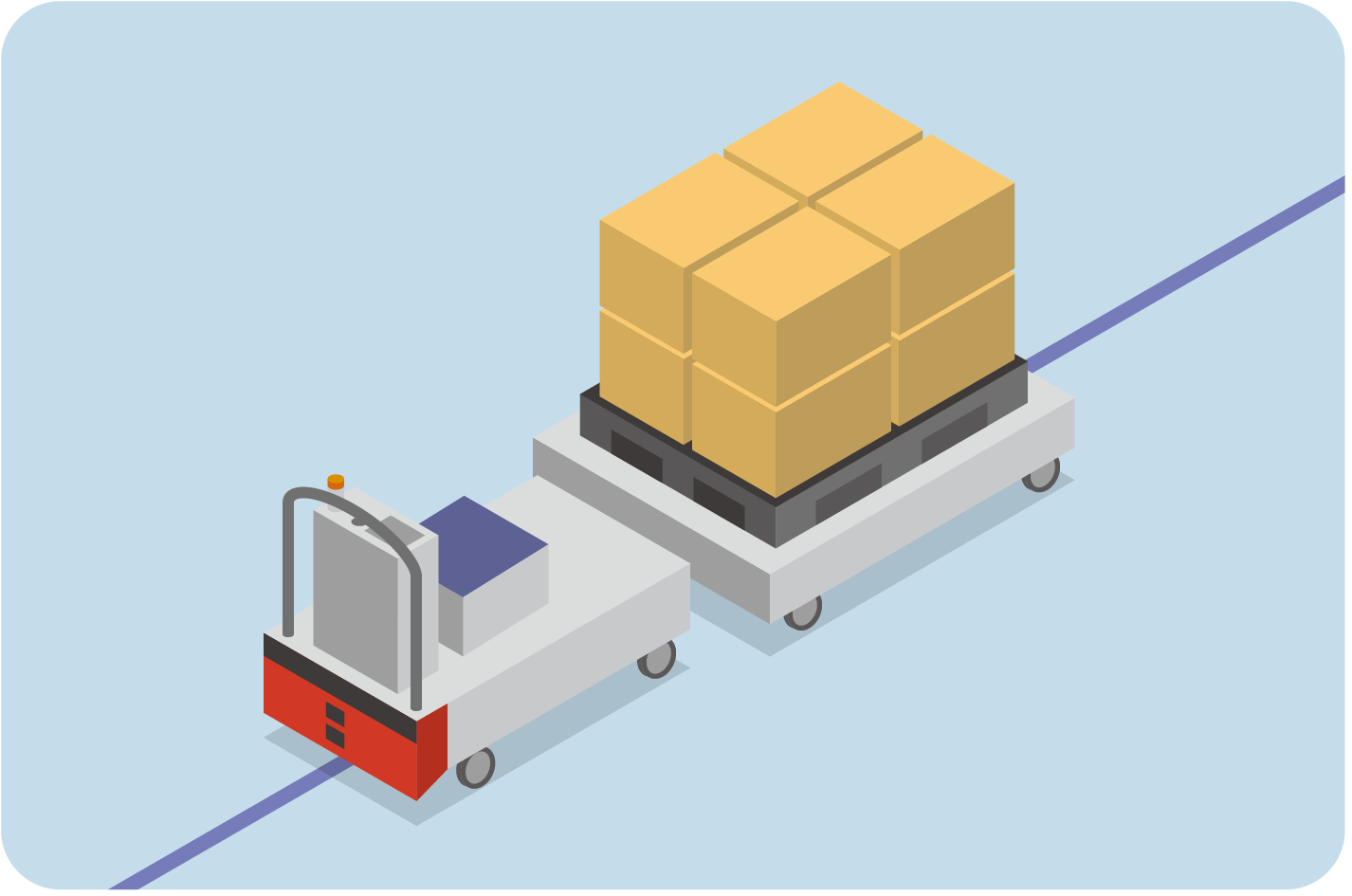

The dolly type pulls the transport cart loaded with pallets. A forklift is used to load and unload the pallets. Low cost because a standard towing vehicle is used.

Transporting pallets placed directly on the floor

Automatically transports pallets placed directly on the floor. Unlike unmanned forklifts, it cannot load and unload pallets onto a pallet rack, but it can move pallets horizontally at low cost.

Recommended AGVs

AGV type palette Eight Series Eight Series

Eight Plus

This transports carts loaded with pallets.

It is used for transporting between storage areas and work processes on the line, and for transporting to the loading and unloading area.

AGV type 6-wheel trolley transport Dragon Series Dragon Series

Dragon3

It transports 6-rin dollies, which are often used in logistics centers.

It slides under the dolly and automatically couples and detaches it.

It can align the dollies at the destination.

AGV type 6-wheel trolley transport Dragon Series Dragon Series

Dragon1

This system transports wide 6-wheel carts. If you need to transport standard 6-wheel carts with a width of 420 mm, please consider the Dragon 3.

AGV type palette AGVs in automobile and other production factories AGV solutions for logistics centers Other types

Lifter AGV

Equipped with a 2-ton lifter as standard, it lifts and transports pallets on the station. It can move forward and backward and spin turn to save space. It is effective for transporting between stockyards and shipping/receiving areas in logistics warehouses, and transporting between processes in production factories.

AGV type palette AGVs in automobile and other production factories AGV solutions for logistics centers Other types

CP type

The CarryBee CP type offers a wide range of benefits in a variety of situations, allowing you to streamline your production process.

CASE4Transporting basket carts

The DB type retracts and automatically couples the trolley. If the trolley is placed in the designated position, the DB type will automatically couple and automatically detach at the destination.

Transport from picking area to shipping area

A loading station is set up in the picking area. After loading is completed, the items are transported to the shipping area. If the loading station is a fixed point, no expensive operation system is required.

Automate manual tasks with mobile robots!!

Logistics AGVFor inquiries and consultations, please click here

If you are interested in AGV solutions for logistics centers, please fill out the form below and submit it.

* indicates required fields.