HOMECase studiesReceiving goods at the distribution center

CASE STUDY

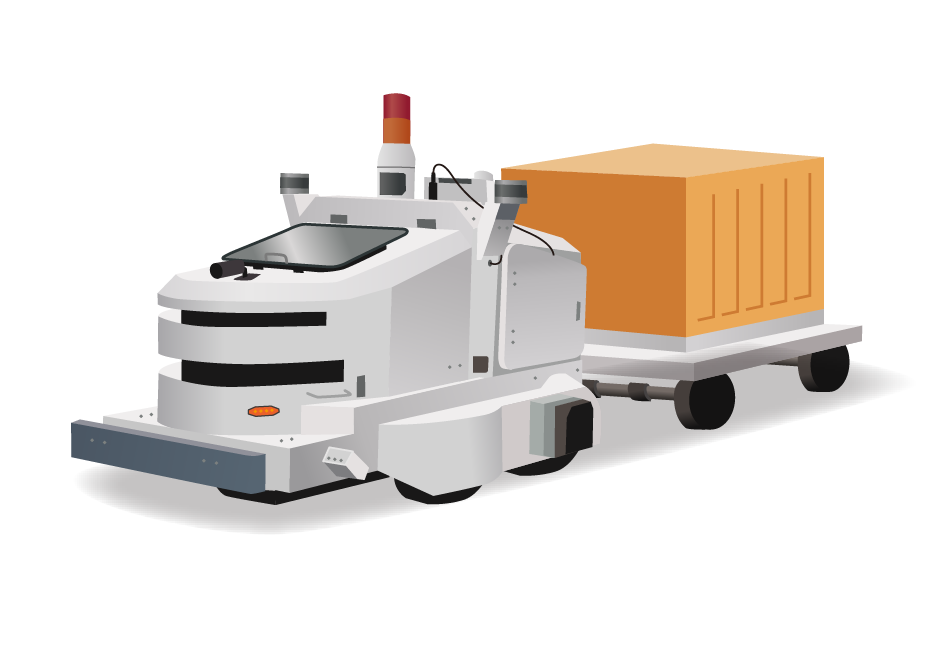

AGV type Low floor L typeReceiving goods at the distribution center

The AGV transports the pallets that have been debunked by the forklift from the truck. The AGV can then enter the elevator and transport them to storage locations on other floors. Previously, the system was based on forklifts, but now it is automated by using a low-floor type.

Introduction

- Introduction Features

- Low-floor L type: Transport weight 500kg

Case Study

If you would like detailed information, please apply below.

You can request more detailed information by phone.

You can request to download detailed information using the information request form below.

You can download CarryBee product documents.

Please apply using the document request form below.

After applying, you will receive an email with a download URL, so please download from there.

AGV PRODUCTS

AGV PRODUCTS

Our original brand, CarryBee, is a pioneer in unmanned transport systems. It has been introduced to many companies both in Japan and overseas, and many people have realized its value.

DB waterproof type

Used in environments with water on the floor or water splashes, such as food factories