HOMECase studiesSearch by industryManufacturing

Case studies

Case studies

AGV CASE STUDY

Here are some examples of customers who have introduced the unmanned AGV CarryBee. Please take a look at the background to the introduction, the reasons for the decision, and the effects, and use this information to help you consider introducing the product.

AGV type CP Type

Transporting pallets placed directly on the floor

Used to store and retrieve palletized products from stock shelves. Horizontal transport by forklift is automated using the CP type. Loading and unloading onto shelves is still done by forklift as before.

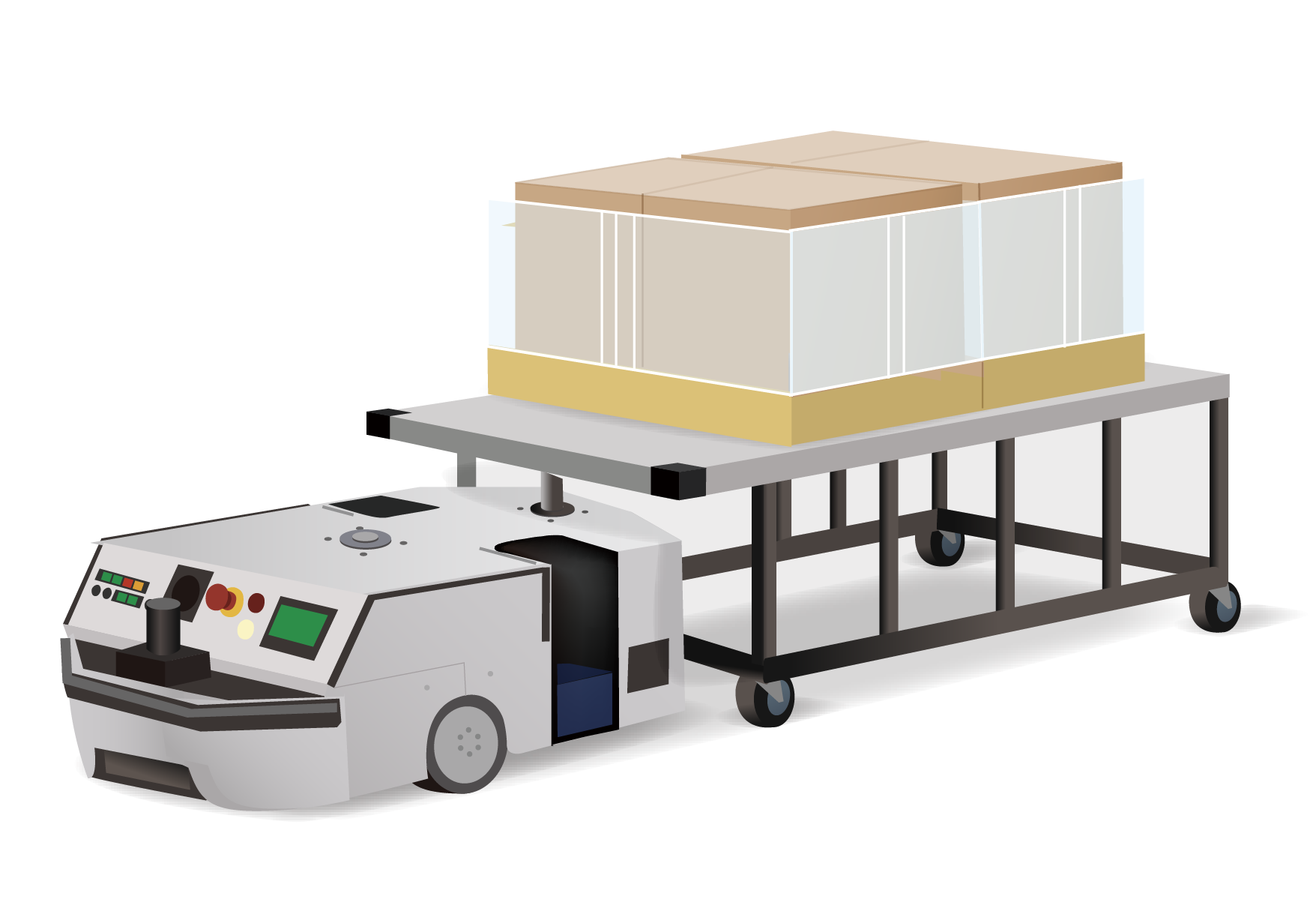

AGV type Lifter AGV

Transportation within the logistics warehouse

Transportation between the storage area and the storage/reception station for incoming and outgoing products. Pallets are transported from the truck to the receiving station by forklift to the storage area. Conventionally, transportation was done by forklift.

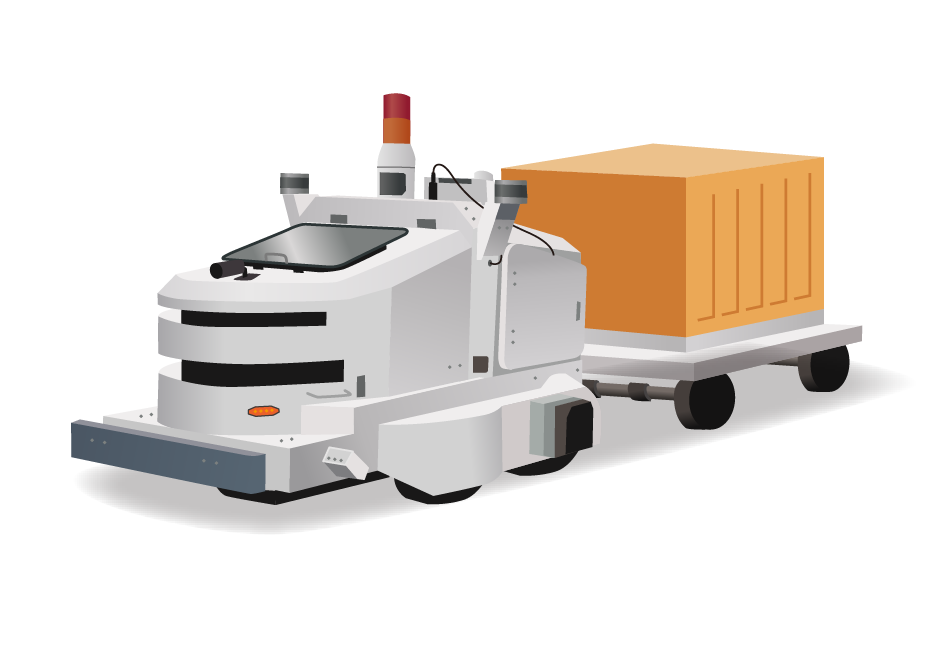

AGV type Outdoor Type

Outdoor transportation within the manufacturing industry

Used for outdoor transport between buildings on the factory grounds. Previously, transport was done with a forklift, but this has been automated with the introduction of the Avance L, which can run outdoors. Loading and unloading of goods at the shipping source and destination is done with a forklift.

AGV type Low floor M type

Cell production introduction

From parts supply to assembly to shipping: Highly efficient production using simple AGVs

solves transportation issues in factories and warehouses.

solves transportation issues in factories and warehouses.

We have a wide variety of AGVs.

You can find the AGV that best suits your needs.

AGV PRODUCTS

AGV PRODUCTS

Our original brand, CarryBee, is a pioneer in unmanned transport systems. It has been introduced to many companies both in Japan and overseas, and many people have realized its value.

DB waterproof type

Used in environments with water on the floor or water splashes, such as food factories