HOMECase studiesSearch by industryLogistics Center

Case studies

Case studies

AGV CASE STUDY

Here are some examples of customers who have introduced the unmanned AGV CarryBee. Please take a look at the background to the introduction, the reasons for the decision, and the effects, and use this information to help you consider introducing the product.

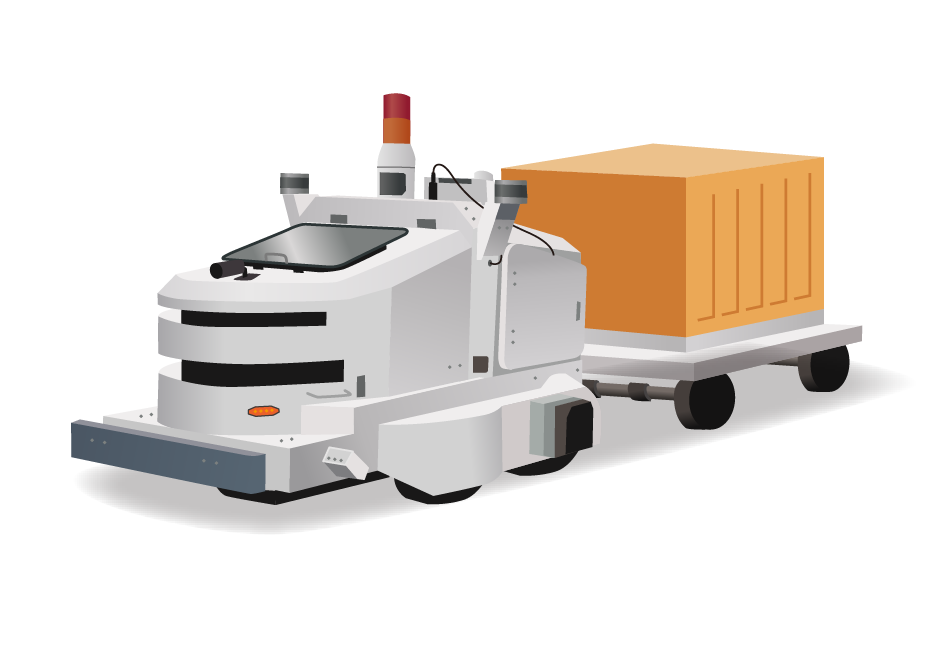

AGV type Low floor L type

Receiving goods at the distribution center

The AGV transports the pallets that have been debunked by the forklift from the truck. The AGV can then enter the elevator and transport them to storage locations on other floors. Previously, the system was based on forklifts, but now it is automated by using a low-floor type.

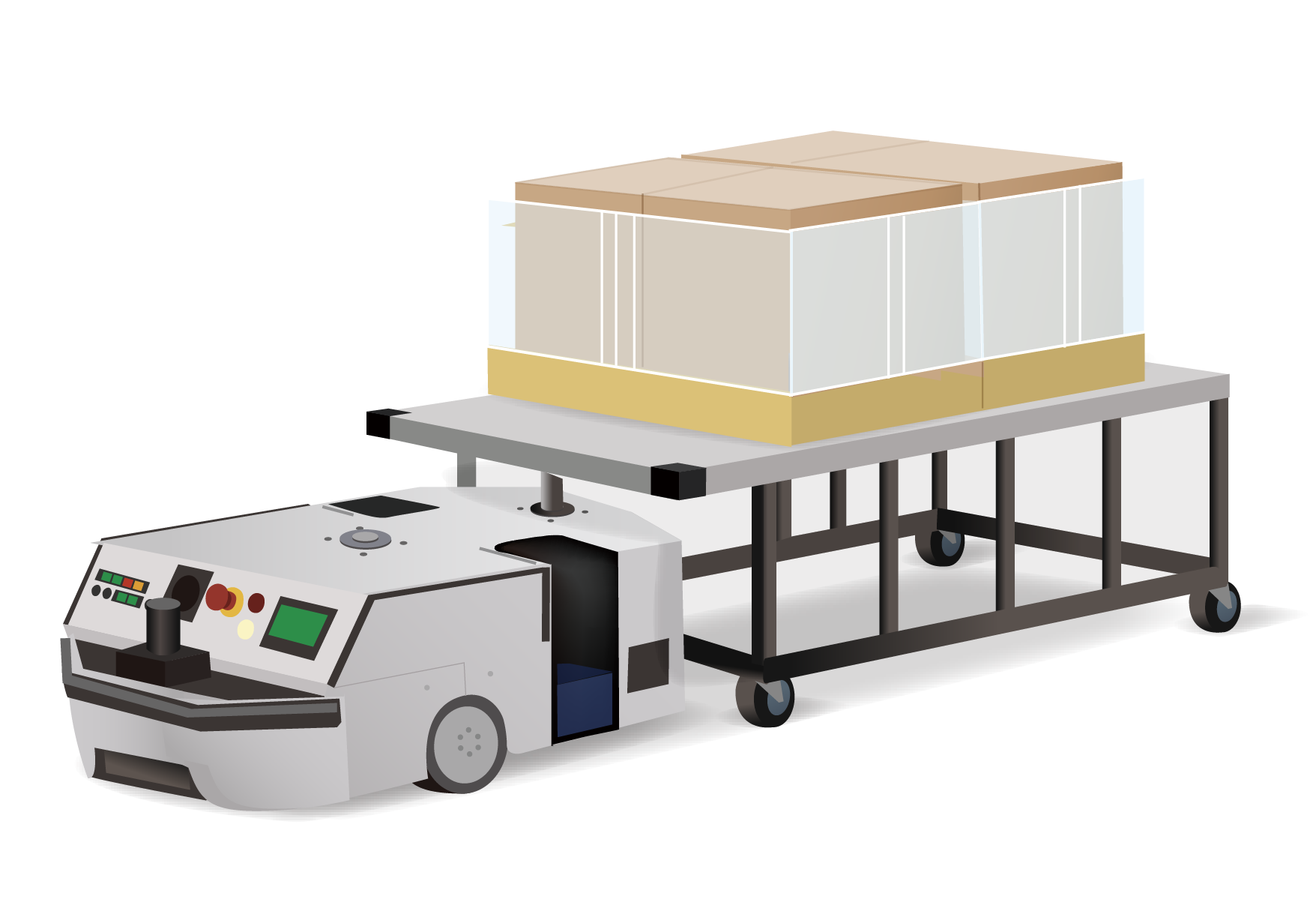

AGV type DB Type

Transporting basket carts

The DB type is used to automate the transportation of the basket cart (roll box pallet) by the worker. The DB type moves backwards and automatically couples the basket cart, and automatically detaches it at the destination.

solves transportation issues in factories and warehouses.

solves transportation issues in factories and warehouses.

We have a wide variety of AGVs.

You can find the AGV that best suits your needs.

AGV PRODUCTS

AGV PRODUCTS

Our original brand, CarryBee, is a pioneer in unmanned transport systems. It has been introduced to many companies both in Japan and overseas, and many people have realized its value.

DB waterproof type

Used in environments with water on the floor or water splashes, such as food factories