1. AGV and cell production

Our engine (ENG) and transaxle (T/A) assembly lines have been mass-produced units, so they have been produced on conveyer lines. However, as history has progressed, the variety of products has increased, and the loss of mixed production on the same line has become apparent.

Therefore, we separated different models with large differences in labor hours and non-mass-produced models with small numbers of units, and moved the remaining mass-produced models to more productive lines, while also working to create profitable lines for non-mass-produced models that are just as profitable as conveyers.

As a result, on the non-mass-produced lines,

- No loss in production with single piece flow

- Resistant to fluctuations in number of pieces

- Anyone can do it, people-friendly

- Low-cost, flexible line

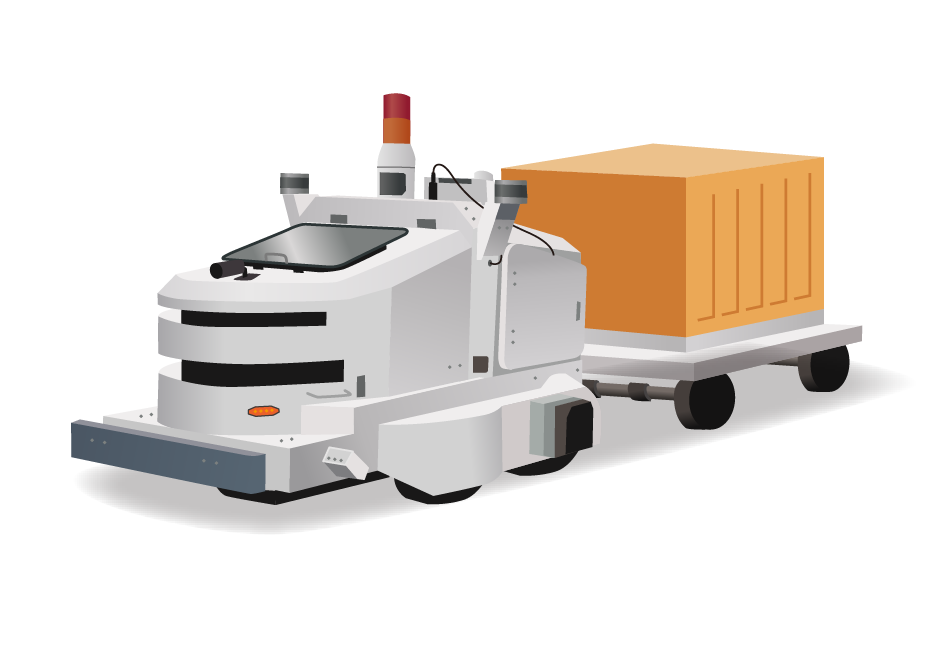

Based on this concept, we have been able to build a line using a cell production system that utilizes simplified automated guided vehicles (AGVs), and we would like to introduce this line here.

2. What is an assembly line using simple AGVs?

Building a cell production (one person complete) assembly line. In non-mass production lines, the number of units varies greatly and models with different labor hours are also produced, so the cell production method generally has great advantages, but it also has disadvantages. By using AGVs, we have adopted a patrol method that minimizes the disadvantages of cell production and makes it easy to manage the pace and expand automation.

| Conveyor system (one process per person) | Cellular Production | ||||

| Division method (partial circulation) |

Patrol method (Rabbit chasing) |

One-person method (bench production) |

|||

| loss | Organization Efficiency | ▲ | ○ | ◎ | ◎ |

| Parts and tools | ○ | ○ | ○ | ▲ | |

| Model setup | ▲ | ▲ | ○ | ○ | |

| Work familiarization | ○ | ○ | ▲ | ▲ | |

| Help each other | ○ | ○ | ▲ | ▲ | |

| Ease of automation | ○ | ○ | ○ | ▲ | |

| Facility cost (I/C) | ○ | ○ | ○ | ▲ | |

| Flexibility | ▲ | ○ | ◎ | ◎ | |

| Production fluctuation tracking ability | ▲ | ○ | ◎ | ◎ | |

| Optimal Production | Production volume | many ←←←←←←← few | |||

| Number of models | few →→→→→→→ many | ||||

| Actual man-hours | many ←←←←←←← few | ||||

As long as the AGV has high stopping position accuracy in relation to the automated vehicle, it does not need to have many functions. This time, we adopted a low-priced simplified model with basic specifications starting from 500,000 yen.

3. Examples of non-mass production assembly lines

1) Launch of T/A non-mass production line…Implementation of integrated AGV production from parts collection to final test

When setting up the line for the new unit, the picking (parts collection) process for gear parts (13 parts), which are the pre- and post-assembly processes, and the test process were also in-line, and the AGV was used to thoroughly complete the work by one person, making it possible to create a line with few people and one-piece flow.

(From a layout by function to a layout by product)

2) Launch of ENG non-mass production line…Introduction of regulated Poka-yoke by AGV

When setting up this new line, the target products were many and small, the man-hours per unit were large, and the processes involved were wide. In this case, a Poka-yoke system was a must for quality assurance, so a “regulated Poka-yoke” was adopted instead of a warning type.

By linking the Poka-yoke system with the AGV launch control, a mechanism was introduced that would prevent the AGV from launching unless the work was completed normally, creating a regulated Poka-yoke line similar to a conveyor line.

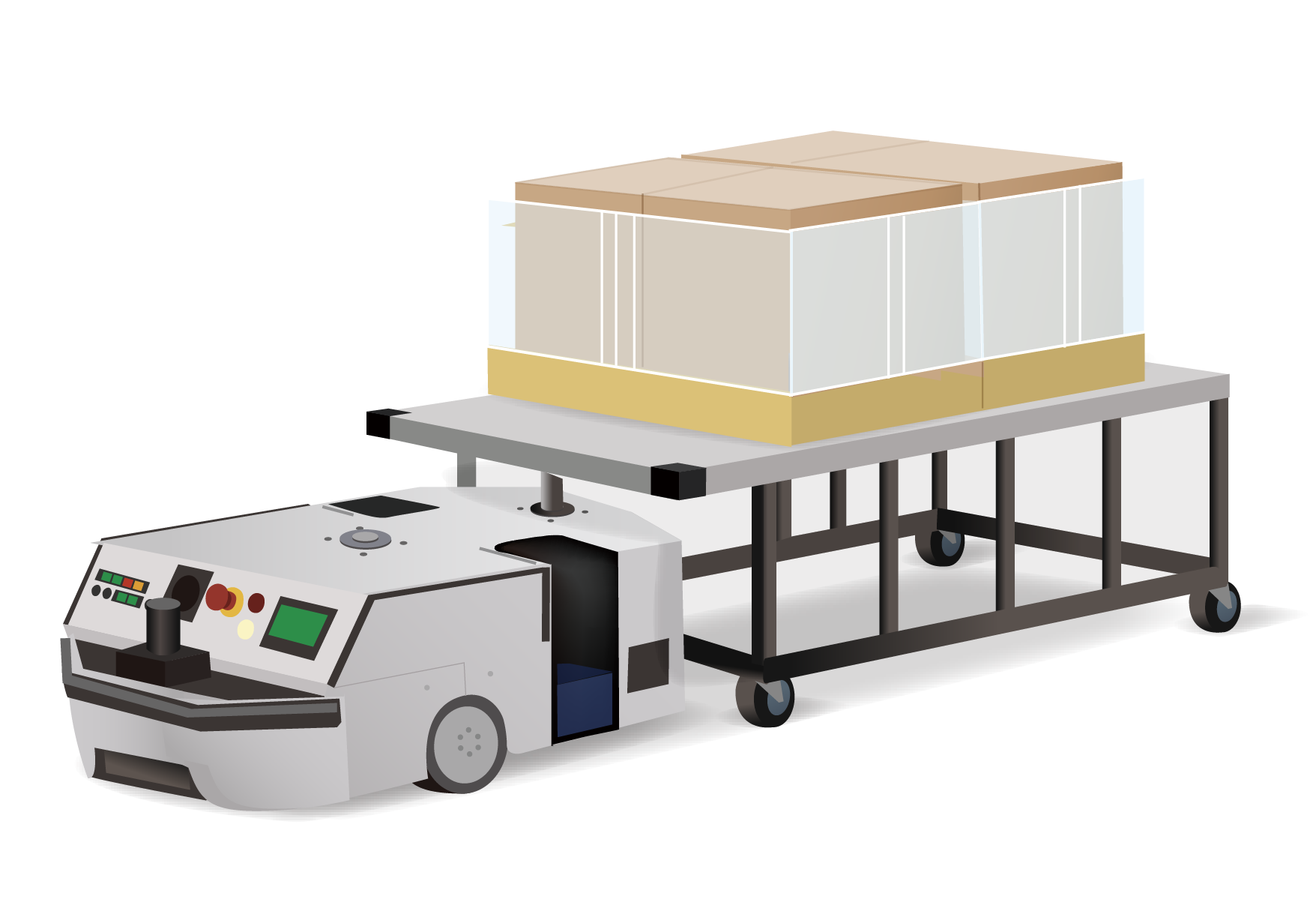

3) Start-up of CVT assembly line – Implementing connection with automatic machines by detaching and attaching assembly jigs

4. Examples of improvements using AGVs other than assembly

1) Improved transport on T/A mass production line

AGVs were originally used for transport between processes, but in the T/A mass production line, sub-tasks were moved between processes with poor composition balance to reduce composition loss.

2) Gear processing (processing – heat treatment – processing)

Gear processing is raw processing – heat treatment (furnace entry) – finishing processing, and an AGV runs between processing and heat treatment to provide tact adjustment functionality.

3) Foundry (LPC pouring – cooling – finishing)

In a foundry with a harsh environment, this transports workpieces between the pouring process – cooling process – finishing process.

The workpieces are hot, and to clear the condition of core sand scattered on the floor, an AGV with sweeper functionality was used.

5. Introduction of the AGV used this time

6. Towards improvements for tomorrow

・A work environment that does not cause stress to workers

・Even for non-mass production, production efficiency is as high as for mass production, and work-in-progress inventory is low

・We are currently making steady improvements with the aim of creating a line that does not cost money.

When installing this new line, in order to deal with difficult work and ensure quality, it was required that the pressing work in the intermediate process be performed with a pressing press rather than a vibrating tool. To incorporate this process into the simplified AGV, the receiving jig itself was made independent, and it was slid from the AGV to the pressing press, allowing the automatic machine to be used without removing and attaching the workpiece.